-

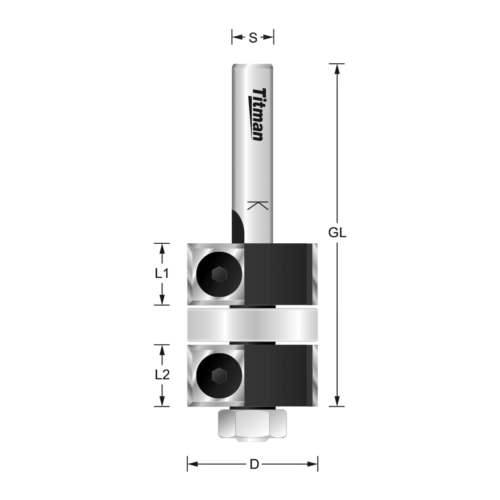

The Titman Multi-Profiler Cutterhead is designed to take the popular WS 40m and 50mm cutter profiles. Using two location pins and a recessed locking flange, the Multi-Profiler is easily changed and secured, offering a whole range of standard and special profiles (specials on request). THIS IS FOR THE TOOL BODY ONLY. A large range of blades are available, download the catalogue pdf on our website, part codes TTFK000 to TTFK100 for blades and TTDK000 to TTDK100 for defectors.

The Titman Multi-Profiler Cutterhead is designed to take the popular WS 40m and 50mm cutter profiles. Using two location pins and a recessed locking flange, the Multi-Profiler is easily changed and secured, offering a whole range of standard and special profiles (specials on request). THIS IS FOR THE TOOL BODY ONLY. A large range of blades are available, download the catalogue pdf on our website, part codes TTFK000 to TTFK100 for blades and TTDK000 to TTDK100 for defectors. -

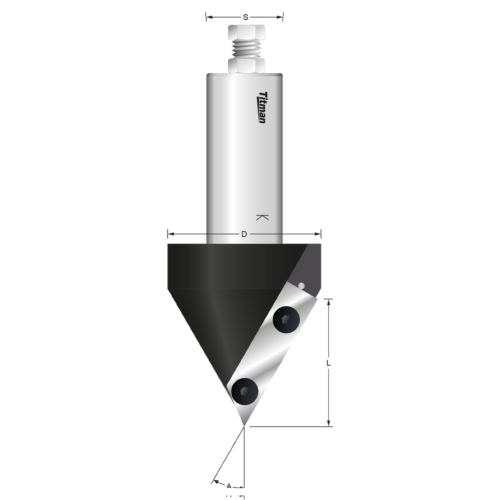

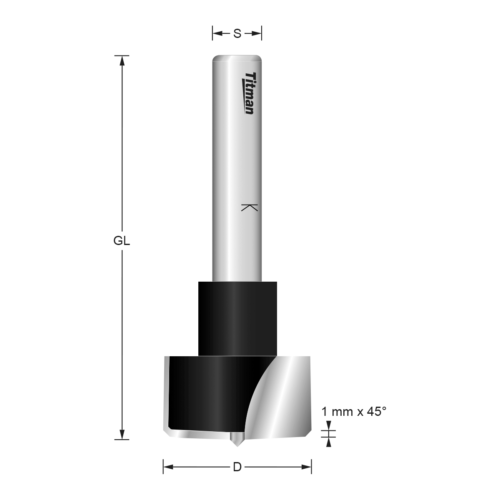

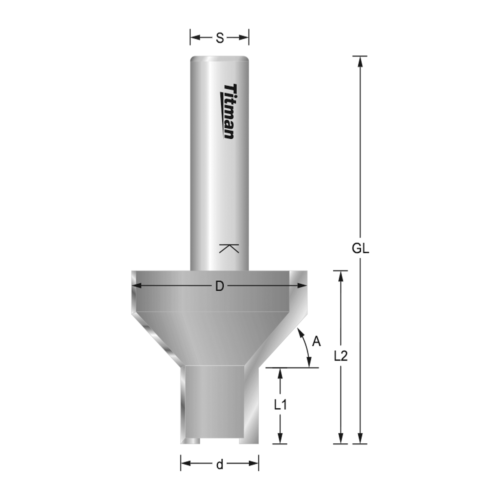

TCT Bevelled A range of various angles of beveled cutters designed to chamfer sections of timber, chipboard and MDF. DESCRIPTION The cutters with reference TTBCF have a tungsten carbide plunging centre tip The cutters with reference TTBC are for profiling only and do not plunge. Angles are measured from the vertical

TCT Bevelled A range of various angles of beveled cutters designed to chamfer sections of timber, chipboard and MDF. DESCRIPTION The cutters with reference TTBCF have a tungsten carbide plunging centre tip The cutters with reference TTBC are for profiling only and do not plunge. Angles are measured from the vertical -

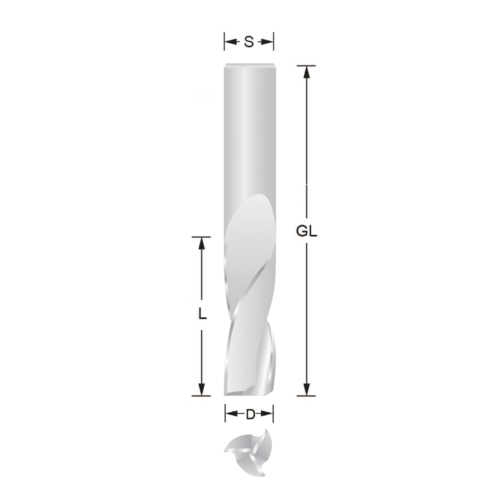

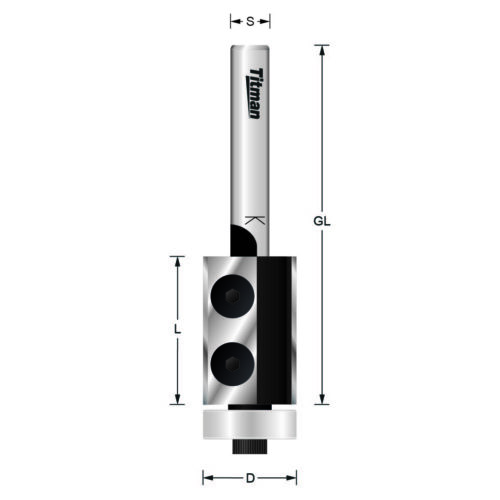

This range are ideal for use on wood, plywood, MDF and other wood composites, plastics, and solid surface materials. Widely used for copy profiling and flush trimming, the replaceable tip design provides a constant diameter and the flexibility of instant tip changes whilst onsite. The L209-OH tip has one cutting edge and is non reversible, the others are reversible. Tips are sold in boxes on 10.

This range are ideal for use on wood, plywood, MDF and other wood composites, plastics, and solid surface materials. Widely used for copy profiling and flush trimming, the replaceable tip design provides a constant diameter and the flexibility of instant tip changes whilst onsite. The L209-OH tip has one cutting edge and is non reversible, the others are reversible. Tips are sold in boxes on 10. -

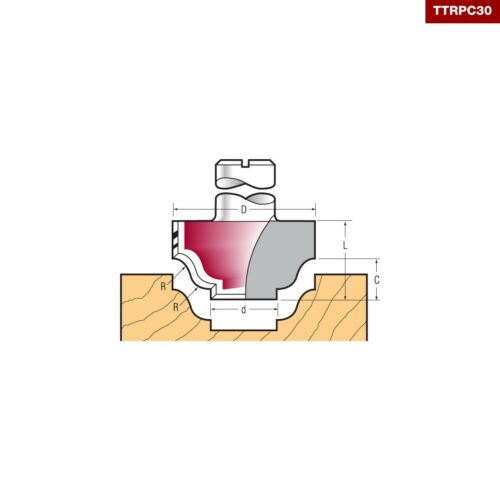

CT Finger Pull Grip Square Bottom For solid handles and pulls on kitchen and wall unit doors, the perfect solutions for providing positive grips and softened, easy-on-the-fingers edges without the need for external hardware. DESCRIPTION TTFPC22 is a variation of TTFPC19 giving a square bottom and undercut. Both of these have a centre tip for plunging

CT Finger Pull Grip Square Bottom For solid handles and pulls on kitchen and wall unit doors, the perfect solutions for providing positive grips and softened, easy-on-the-fingers edges without the need for external hardware. DESCRIPTION TTFPC22 is a variation of TTFPC19 giving a square bottom and undercut. Both of these have a centre tip for plunging -

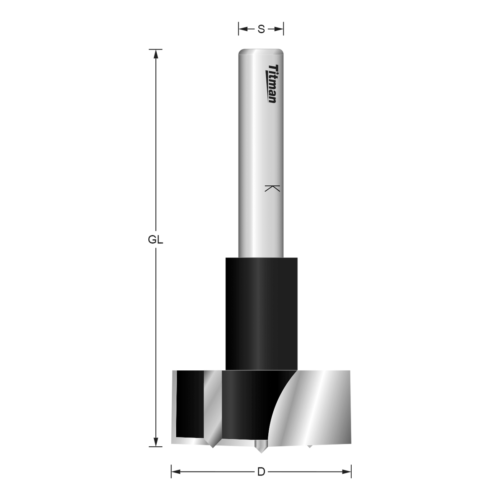

DESCRIPTION 2 wing with centre point and with or without scribers and parallel shanks. Right hand with centre point. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM.

DESCRIPTION 2 wing with centre point and with or without scribers and parallel shanks. Right hand with centre point. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM. -

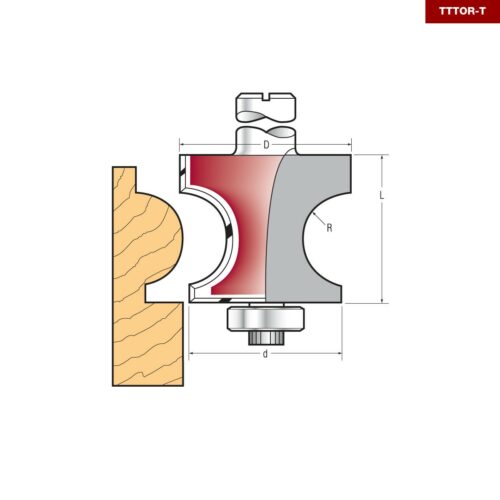

TCT Multi-Mould DESCRIPTION TTTOR25 gives an ornate moulding used in full or in part. TTTOR22 is a possible picture rail and cover mould cutter. TTTOR27 ideal to use the complete mould or part for short production runs. Excellent cutter to produce ornate skirting and architrave moulding. TTTOR-B gives a deep cavetto effect with a bead to break up the line of the mould. The fine lines of this cutter make it an excellent choice for matching skirting and architrave. TTTOR-C is a variation of the Torus Mould (TTTOR-T).

TCT Multi-Mould DESCRIPTION TTTOR25 gives an ornate moulding used in full or in part. TTTOR22 is a possible picture rail and cover mould cutter. TTTOR27 ideal to use the complete mould or part for short production runs. Excellent cutter to produce ornate skirting and architrave moulding. TTTOR-B gives a deep cavetto effect with a bead to break up the line of the mould. The fine lines of this cutter make it an excellent choice for matching skirting and architrave. TTTOR-C is a variation of the Torus Mould (TTTOR-T). -

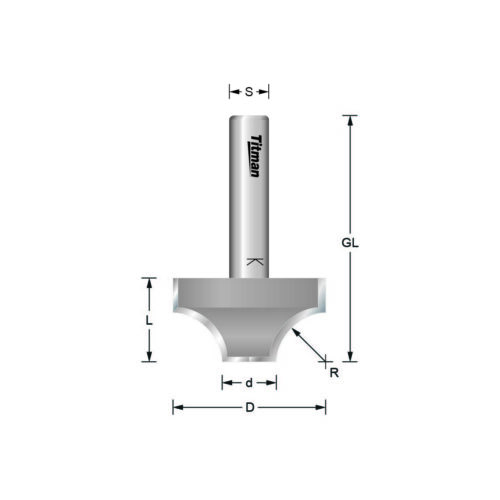

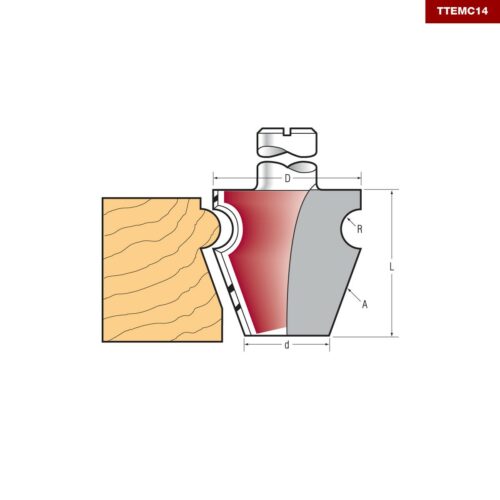

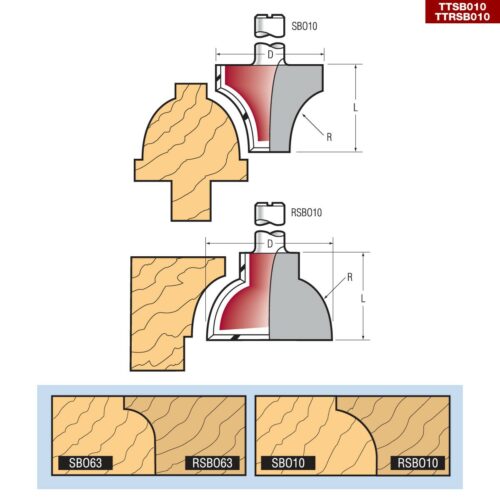

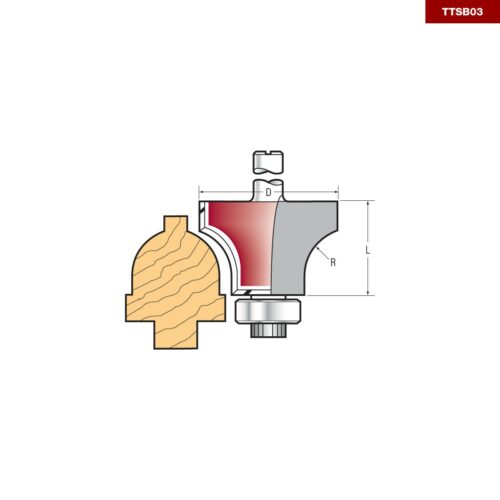

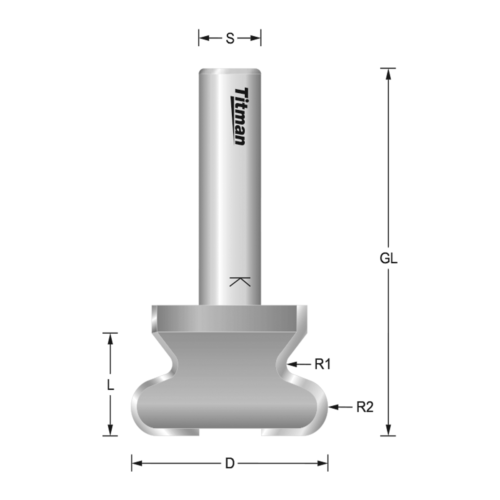

TCT Edge Moulding Shallow Bead A shallow radius style bull nose cutter ideal for a hand hold which is able to plunge into the centre of a board. Designed to finish solid edged worktops for kitchens or display work areas. These have a shallow radius DESCRIPTION The shallow arc is ideal for a hand hold shape rather than a full 180-degree round over, this also has short flats above and below the cutter arc which can produce a small quirk effect for an edge mould for example

TCT Edge Moulding Shallow Bead A shallow radius style bull nose cutter ideal for a hand hold which is able to plunge into the centre of a board. Designed to finish solid edged worktops for kitchens or display work areas. These have a shallow radius DESCRIPTION The shallow arc is ideal for a hand hold shape rather than a full 180-degree round over, this also has short flats above and below the cutter arc which can produce a small quirk effect for an edge mould for example -

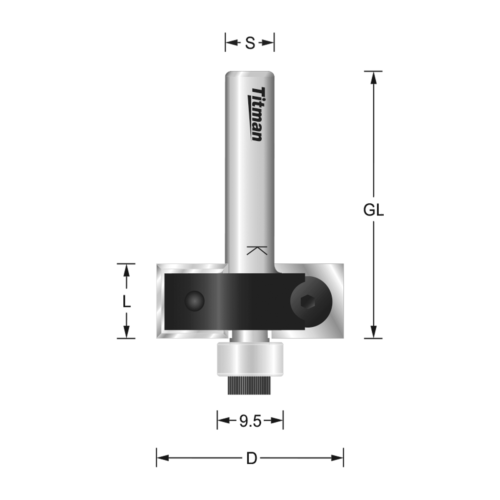

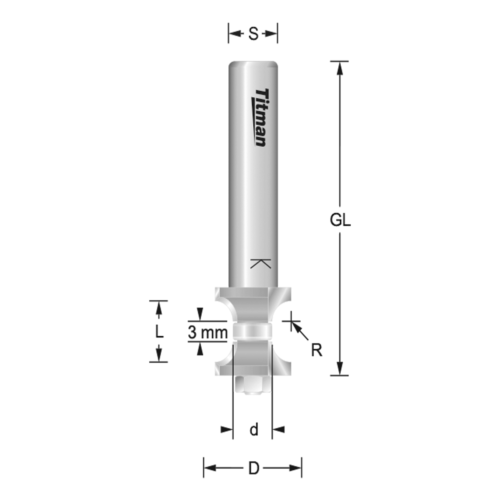

A range of rebate cutters bearing guided, bearings can be changed to a different diameter to produce various rebate depths. The TTRCB95-1/2RT and TTRCB95-8RT are fitted with the TT3/8-B37514 bearing and also come with the TT1/2-B127, TTB15 and TTB19 bearings. The TTRCb9512RT is fitted with 2 - TT1/2-B127 bearings and can then be used in conjunction with the TTRR range of aluminium sleeves to produce the various rebate depths. These rings are placed in the middle of the 2 bearings which then keep them secure whilst routing. If you take the diameter dimension of the cutter minus the diameter dimension of the ring and divide by 2 this will give you the rebate depth. Tips are reversible and are sold in boxes of 10

A range of rebate cutters bearing guided, bearings can be changed to a different diameter to produce various rebate depths. The TTRCB95-1/2RT and TTRCB95-8RT are fitted with the TT3/8-B37514 bearing and also come with the TT1/2-B127, TTB15 and TTB19 bearings. The TTRCb9512RT is fitted with 2 - TT1/2-B127 bearings and can then be used in conjunction with the TTRR range of aluminium sleeves to produce the various rebate depths. These rings are placed in the middle of the 2 bearings which then keep them secure whilst routing. If you take the diameter dimension of the cutter minus the diameter dimension of the ring and divide by 2 this will give you the rebate depth. Tips are reversible and are sold in boxes of 10 -

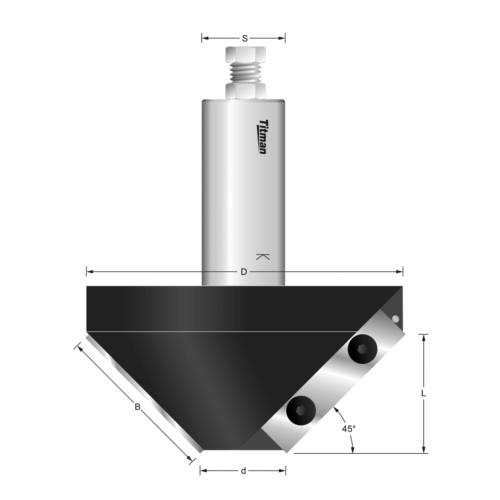

TCT Chamfering Edge Chamfering Edge Cutters. Reducing and Chamfering. DESCRIPTION TTCEC45, TTCECR45, TTLTC4, TTLTCR4, TTLTC63, TTLTCR63 are non plunge but with bottom cut facility. TTCECR45 is the reverse of TTCEC45. TTCECR45L is the reverse of TTCEC45L. TTLTC4 and TTLTCR4 give a lambs tongue effect as TTROB range. TTLTCR4 is the reverse of TTLTC4. TTLTCR63 is the reverse of TTLTC63.

TCT Chamfering Edge Chamfering Edge Cutters. Reducing and Chamfering. DESCRIPTION TTCEC45, TTCECR45, TTLTC4, TTLTCR4, TTLTC63, TTLTCR63 are non plunge but with bottom cut facility. TTCECR45 is the reverse of TTCEC45. TTCECR45L is the reverse of TTCEC45L. TTLTC4 and TTLTCR4 give a lambs tongue effect as TTROB range. TTLTCR4 is the reverse of TTLTC4. TTLTCR63 is the reverse of TTLTC63. -

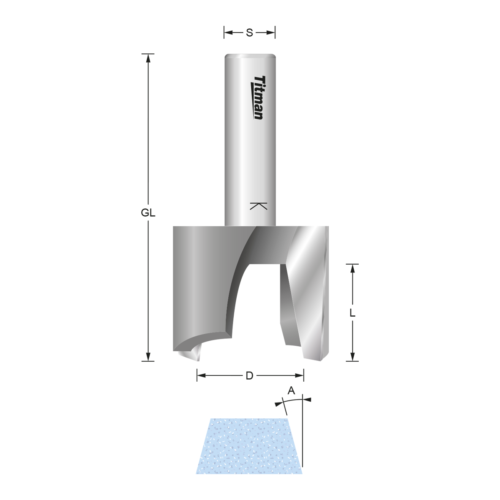

DESCRIPTION Ideal for veining work, freehand decor for panels and useful for character lining work on sign writing applications in solid timbers. The angle ( measurement A ) is measured from the horizontal. TTVGC45SF-1/2, TTVGC45SF-1/4, TTVGC45SF-12, TTVGC60SF-1/2, TTVGC60SF-1/4, TTVGC60SF-12, TTVGC60SF-8 cut to a point. TTVGCB45-1/4, TTVGCB60-127-1/4 have a shank mounted bearing.

DESCRIPTION Ideal for veining work, freehand decor for panels and useful for character lining work on sign writing applications in solid timbers. The angle ( measurement A ) is measured from the horizontal. TTVGC45SF-1/2, TTVGC45SF-1/4, TTVGC45SF-12, TTVGC60SF-1/2, TTVGC60SF-1/4, TTVGC60SF-12, TTVGC60SF-8 cut to a point. TTVGCB45-1/4, TTVGCB60-127-1/4 have a shank mounted bearing. -

Solid Carbide Burrs Ideally suited for freehand stock removal, weld preparation and finishing of nimonic alloy components. A smooth finish can be achieved on metal, plastic and other materials. RPM for each product in this range: TTSCB1 - 10,000-30,000 TTSCB2 - 20,000-90,000 TTSCB3 - 10,000-30,000 TTSCB4 - 20,000-50,000 TTSCB5 - 10,000-30,000 TTSCB6 - 20,000-50,000 TTSCB7 - 10,000-30,000 TTSCB8 - 10,000-30,000 TTSCB9 and TTSCB95 - 20,000-50,000 TTSCB10 - 20,000-50,000 TTSCB11-TTSCB14 - 20,000-50,006

Solid Carbide Burrs Ideally suited for freehand stock removal, weld preparation and finishing of nimonic alloy components. A smooth finish can be achieved on metal, plastic and other materials. RPM for each product in this range: TTSCB1 - 10,000-30,000 TTSCB2 - 20,000-90,000 TTSCB3 - 10,000-30,000 TTSCB4 - 20,000-50,000 TTSCB5 - 10,000-30,000 TTSCB6 - 20,000-50,000 TTSCB7 - 10,000-30,000 TTSCB8 - 10,000-30,000 TTSCB9 and TTSCB95 - 20,000-50,000 TTSCB10 - 20,000-50,000 TTSCB11-TTSCB14 - 20,000-50,006 -

TCT Adjustable Top and Bottom Chamfer with Bearing DESCRIPTION For bevelling and trimming the top and bottom edges of the workpiece. Adjust the four wing trimmer blocks with spacers for differing widths of material. Maximum material thickness 15mm for the DCB16 and is fixed Maximum material thickness 32mm, minimum material thickness 16mm for the BCS38. Maximum material thickness 36mm, minimum material thickness 19mm for the BGAC45. To extend the life of cutting edges use 26mm bearing.

TCT Adjustable Top and Bottom Chamfer with Bearing DESCRIPTION For bevelling and trimming the top and bottom edges of the workpiece. Adjust the four wing trimmer blocks with spacers for differing widths of material. Maximum material thickness 15mm for the DCB16 and is fixed Maximum material thickness 32mm, minimum material thickness 16mm for the BCS38. Maximum material thickness 36mm, minimum material thickness 19mm for the BGAC45. To extend the life of cutting edges use 26mm bearing. -

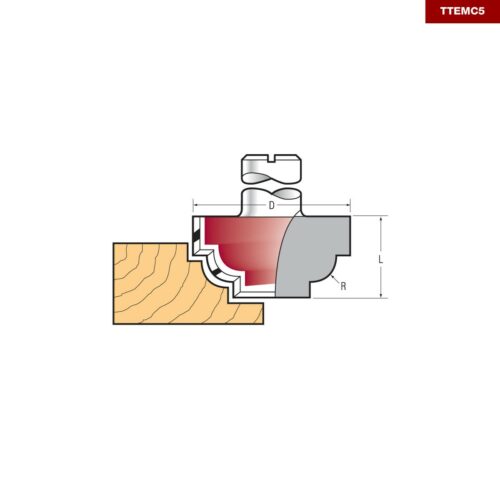

TCT Tapered Plug Making Plug making cutter producing a tapered plug to be driven in and tightly secured. To avoid cutter deflection use this TTTPC range of cutters only on Pillar Drilling machines and do not exceed 3,000 RPM. Feed evenly into material. DESCRIPTION Plug making cutter producing a tapered plug to be driven in and tightly secured. To avoid cutter deflection use this TTTPC range of cutters only on Pillar Drilling machines and do not exceed 3,000 RPM. Feed evenly into material.

TCT Tapered Plug Making Plug making cutter producing a tapered plug to be driven in and tightly secured. To avoid cutter deflection use this TTTPC range of cutters only on Pillar Drilling machines and do not exceed 3,000 RPM. Feed evenly into material. DESCRIPTION Plug making cutter producing a tapered plug to be driven in and tightly secured. To avoid cutter deflection use this TTTPC range of cutters only on Pillar Drilling machines and do not exceed 3,000 RPM. Feed evenly into material.