-

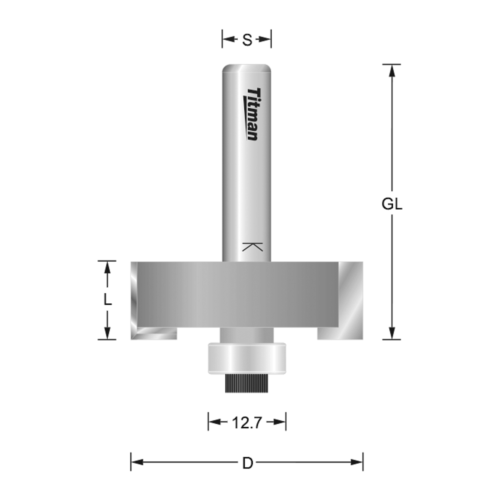

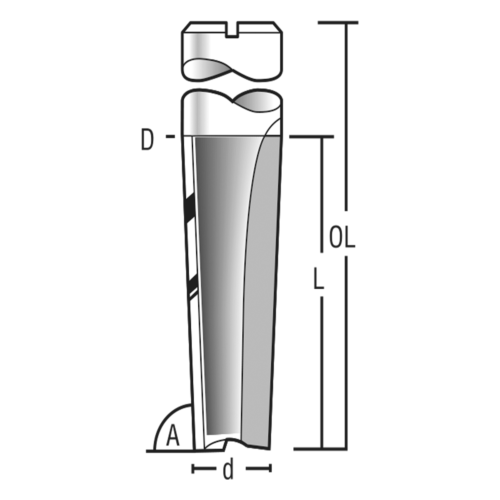

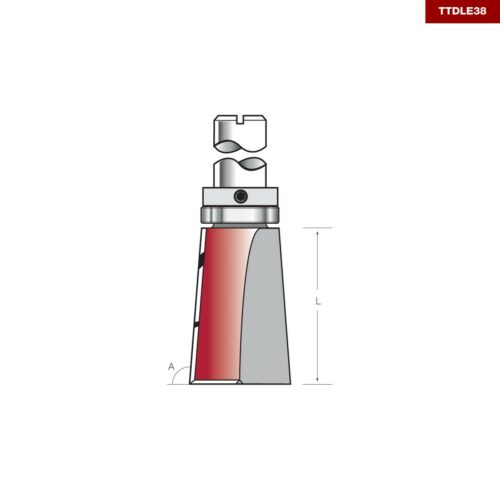

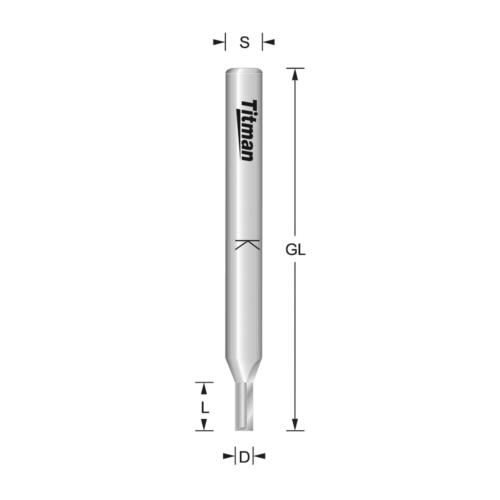

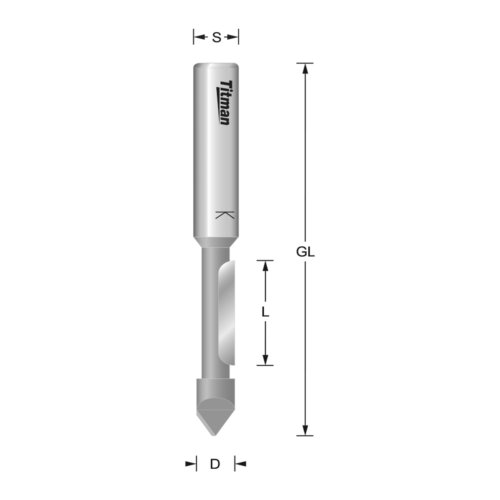

Panel Pilot Pierce and Trim TCT A very popular robust solid end plunge and guided panel pilot or pierce and trim cutter widely used within the caravan, mobile home and motor home manufacture industry, this is ideal for cutting apertures and openings in the walls and floor pans. DESCRIPTION The V point end design allows the cutter to plunging into the board and the solid guide immediately behind this is used as the follower. There are two options here in design with the single flute and double flute versions. A single flute cuts faster with good chip clearance which then has less friction, but can leave a rougher cut on certain materials. A double flute produces a cleaner finish with a slower feed rate The TTPDT127-1/2SF has a solid guide at the end and in the middle of two cutting edges allowing for the simultaneous trimming of a top and bottom covering over the wooden frame construction.

Panel Pilot Pierce and Trim TCT A very popular robust solid end plunge and guided panel pilot or pierce and trim cutter widely used within the caravan, mobile home and motor home manufacture industry, this is ideal for cutting apertures and openings in the walls and floor pans. DESCRIPTION The V point end design allows the cutter to plunging into the board and the solid guide immediately behind this is used as the follower. There are two options here in design with the single flute and double flute versions. A single flute cuts faster with good chip clearance which then has less friction, but can leave a rougher cut on certain materials. A double flute produces a cleaner finish with a slower feed rate The TTPDT127-1/2SF has a solid guide at the end and in the middle of two cutting edges allowing for the simultaneous trimming of a top and bottom covering over the wooden frame construction. -

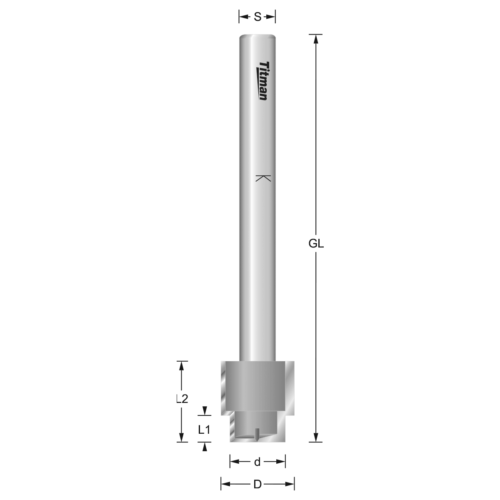

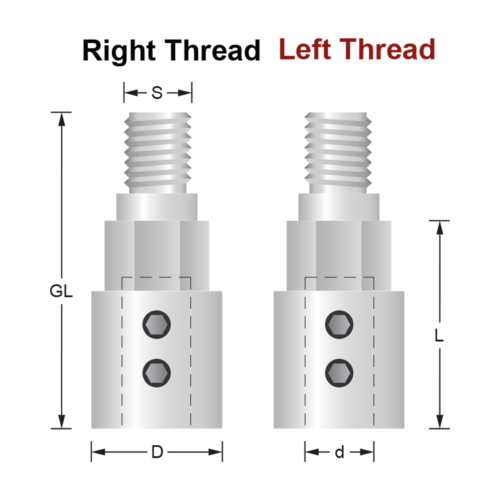

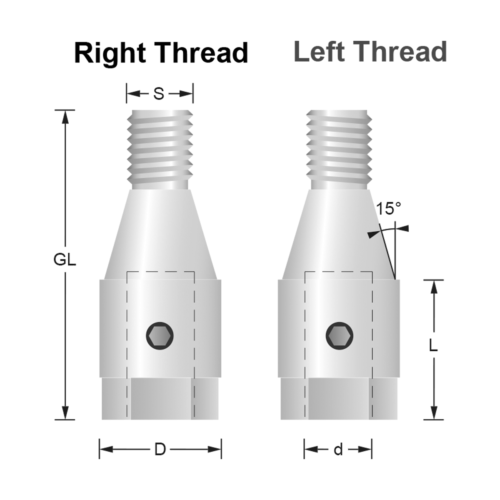

Drill holder for Morbidelli, Biesse, Weeke, Reimall, Torwegge, Busellato, Bottcher, Gessner, Ayen Available in different thread sizes and in Right Hand (part codes suffixed RH) and Left Hand (part codes suffixed LH) threads to suit a variety of popular machines. DESCRIPTION Available in different thread sizes and in Right Hand (part codes suffixed RH) and Left Hand (part codes suffixed LH) threads to suit a variety of popular machines. Available with spigot if required. TTMB10M has a 10mm thread and suits Morbidelli, Biesse, Weeke, Reimall, Torwegge, Busellato, Bottcher, Gessner, Ayen machines. TTAB10M has a 10mm thread and suits Alberti, SCM, Vitap, Balestrini, Bilek, Ombe machines. TTNM8M has a 8mm thread and suits Nottmeyer machines. TTMB10BR has a 3/8 BSF thread and suits Brookman machines: TTMB10RY has a 3/8 BSW thread and suits Rye machines: Please ensure correct variation is selected when ordering. For machines not listed here please contact the Sales Department with details of thread size and type, aperture size and overall lengths for advice.

Drill holder for Morbidelli, Biesse, Weeke, Reimall, Torwegge, Busellato, Bottcher, Gessner, Ayen Available in different thread sizes and in Right Hand (part codes suffixed RH) and Left Hand (part codes suffixed LH) threads to suit a variety of popular machines. DESCRIPTION Available in different thread sizes and in Right Hand (part codes suffixed RH) and Left Hand (part codes suffixed LH) threads to suit a variety of popular machines. Available with spigot if required. TTMB10M has a 10mm thread and suits Morbidelli, Biesse, Weeke, Reimall, Torwegge, Busellato, Bottcher, Gessner, Ayen machines. TTAB10M has a 10mm thread and suits Alberti, SCM, Vitap, Balestrini, Bilek, Ombe machines. TTNM8M has a 8mm thread and suits Nottmeyer machines. TTMB10BR has a 3/8 BSF thread and suits Brookman machines: TTMB10RY has a 3/8 BSW thread and suits Rye machines: Please ensure correct variation is selected when ordering. For machines not listed here please contact the Sales Department with details of thread size and type, aperture size and overall lengths for advice. -

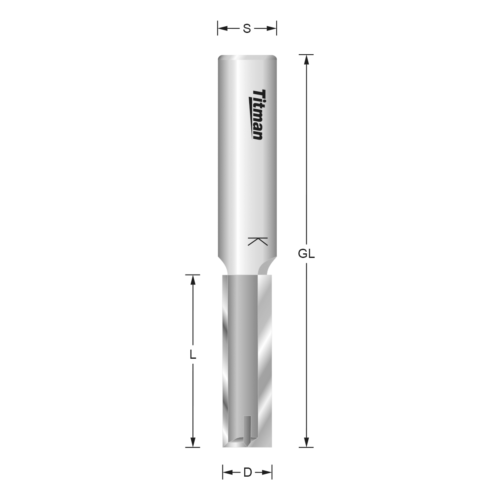

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool. -

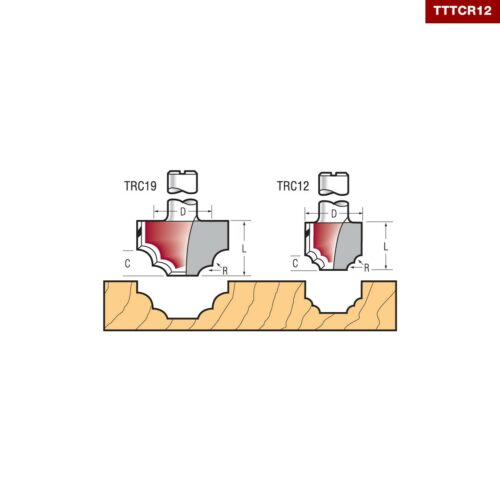

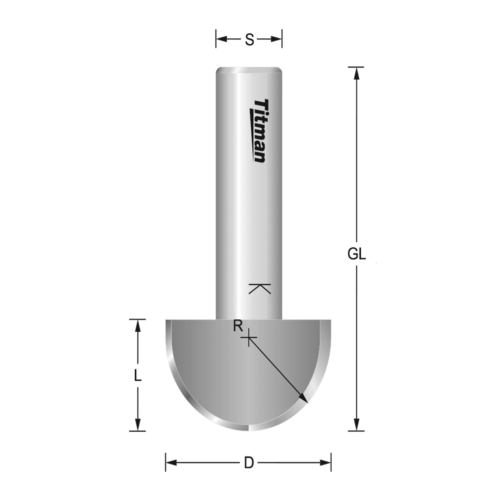

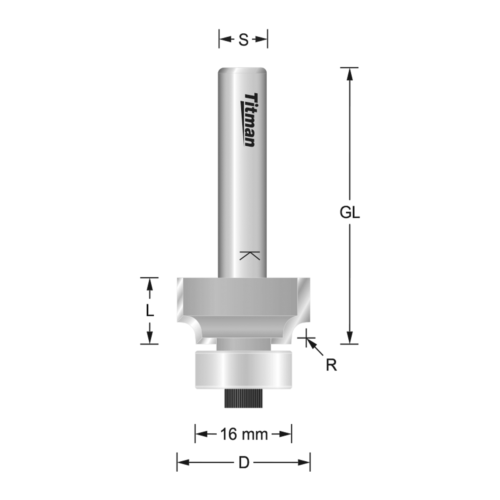

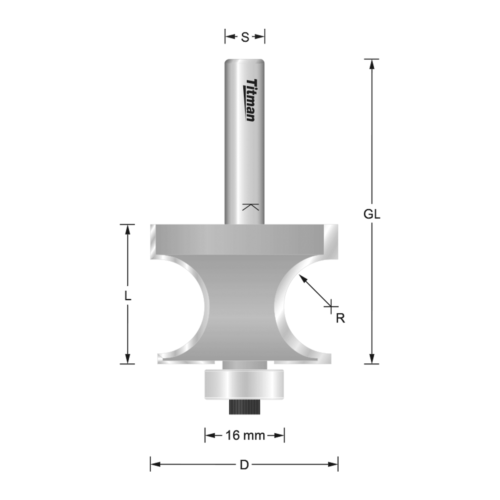

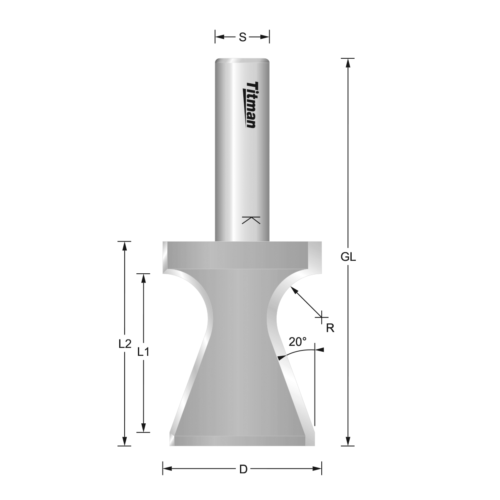

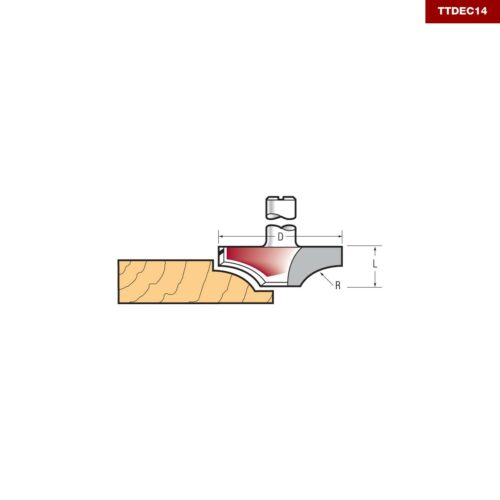

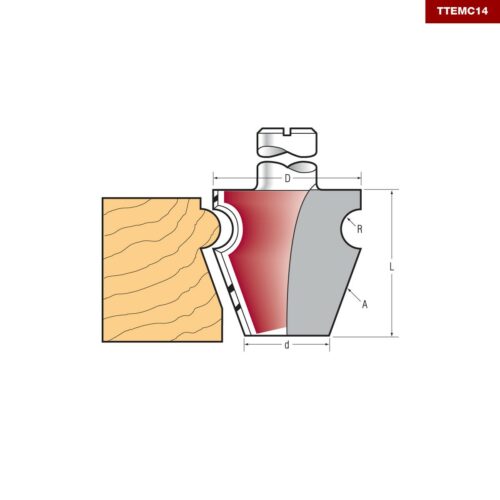

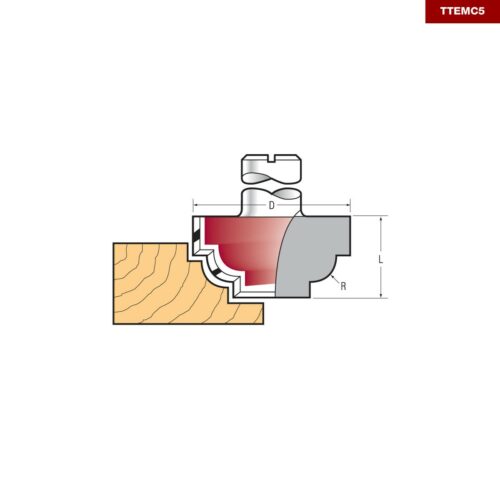

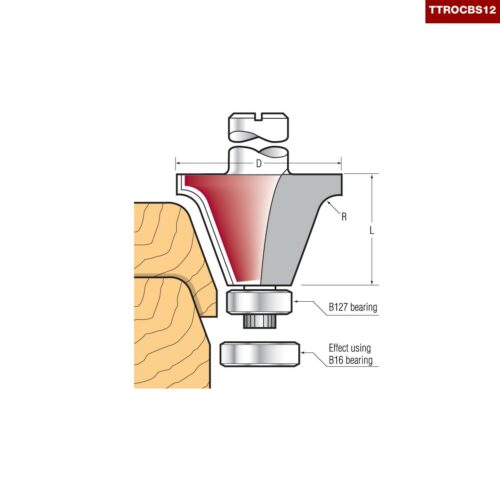

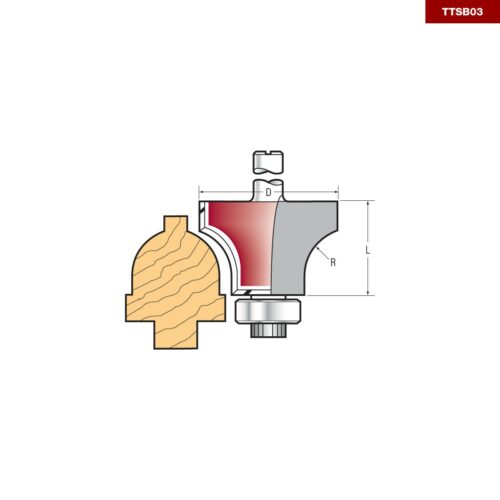

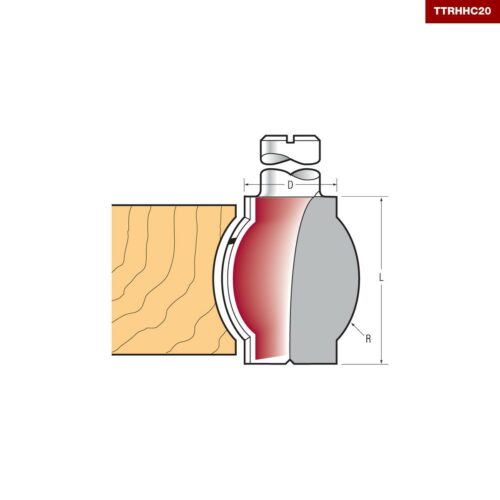

Used to create a fluting effect on the edge of furniture. TTRWHC range are used to create a fluting effect on the edge of furniture. TTSBCB range has a removeable bearing system. When requiring a self guiding effect ensure the jig has clearance between workpiece and bottom of cutter. TTHHC20 and TTRHHC20 complement each other and when used together perform the cuts needed to form a drop leaf table joint. Please note some of these products are Made To Order.

Used to create a fluting effect on the edge of furniture. TTRWHC range are used to create a fluting effect on the edge of furniture. TTSBCB range has a removeable bearing system. When requiring a self guiding effect ensure the jig has clearance between workpiece and bottom of cutter. TTHHC20 and TTRHHC20 complement each other and when used together perform the cuts needed to form a drop leaf table joint. Please note some of these products are Made To Order. -

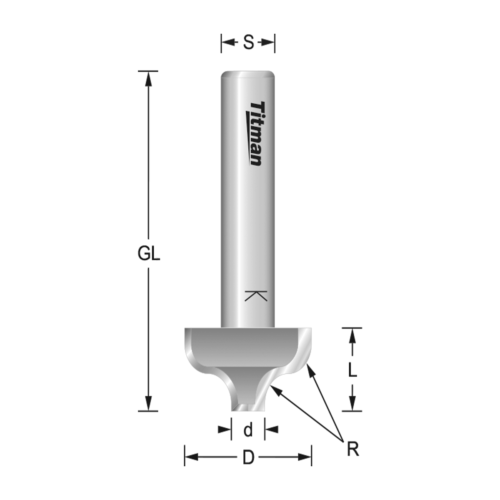

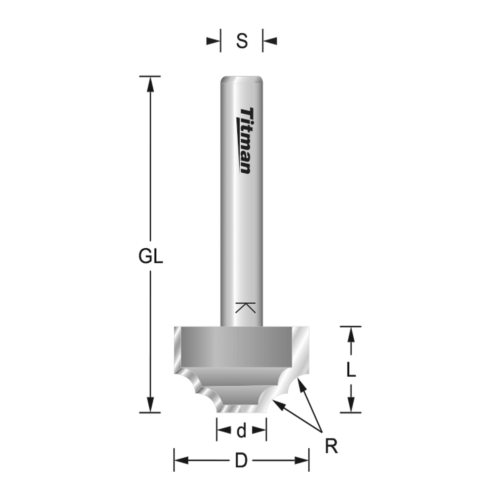

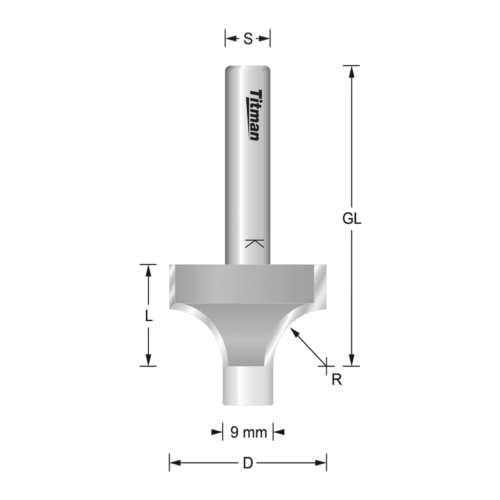

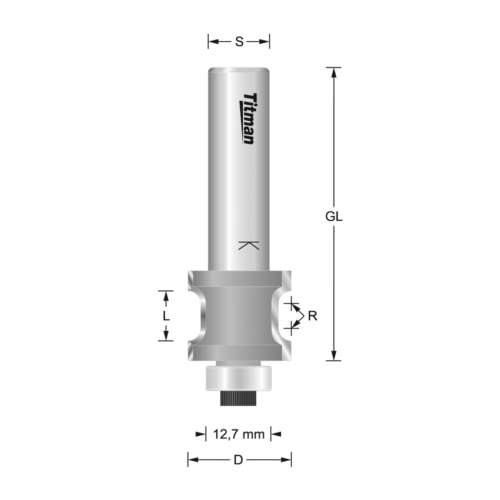

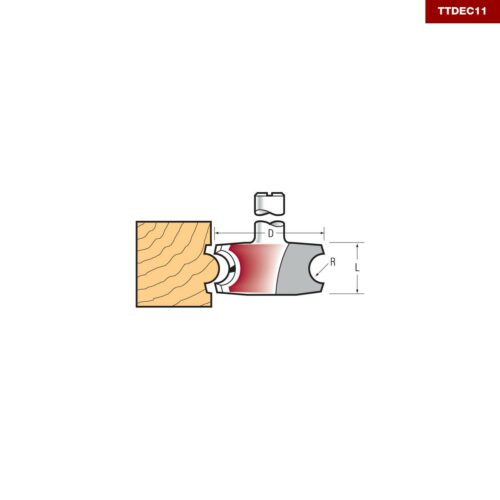

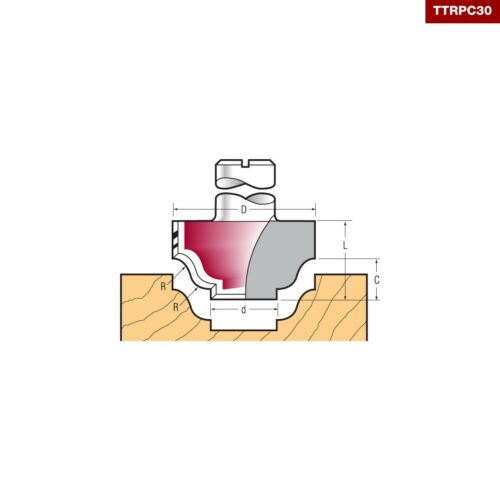

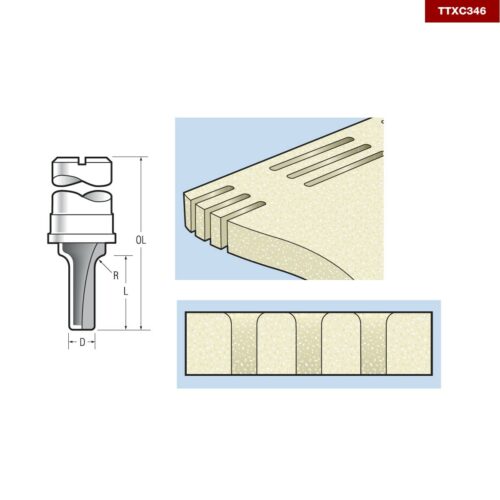

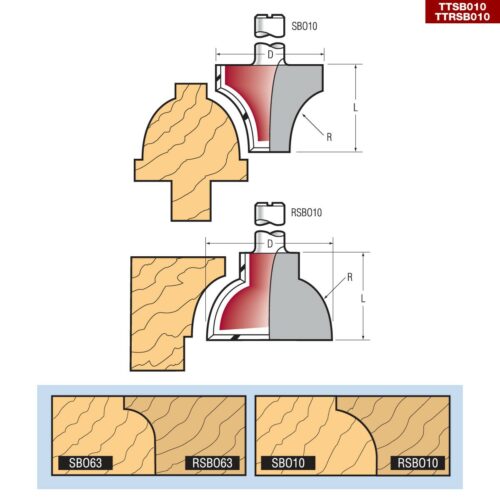

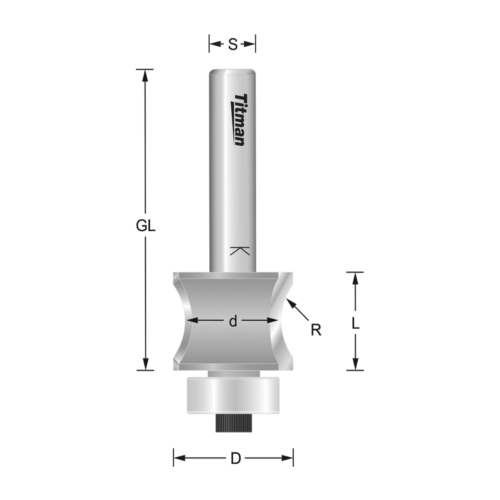

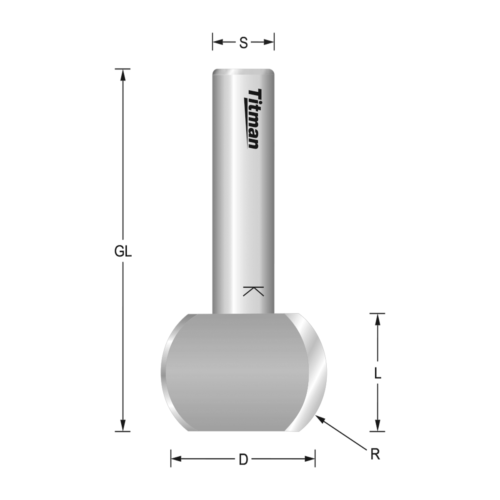

This range of bead cutters produce mouldings to highlight features such as fascia rails, chair backs or decorative sections 'planted' on bedroom furniture to bring a line and feature to a continuous layout. TTDSB4 is a sunken flute cutter with a shallow radius to produce a soft effect. An ideal cutter to produce fluted pillars, for fire surrounds and 'gable ends' on bedroom furniture. Useful cutter to cut on a glue joint to hide the glue line. TTDSB5 is a sunk bead mould perfect for finishing wall unit facias and cover moulds on window sections. TTDSB7 is ideal for fluting or decorating solid surrounds.

This range of bead cutters produce mouldings to highlight features such as fascia rails, chair backs or decorative sections 'planted' on bedroom furniture to bring a line and feature to a continuous layout. TTDSB4 is a sunken flute cutter with a shallow radius to produce a soft effect. An ideal cutter to produce fluted pillars, for fire surrounds and 'gable ends' on bedroom furniture. Useful cutter to cut on a glue joint to hide the glue line. TTDSB5 is a sunk bead mould perfect for finishing wall unit facias and cover moulds on window sections. TTDSB7 is ideal for fluting or decorating solid surrounds. -

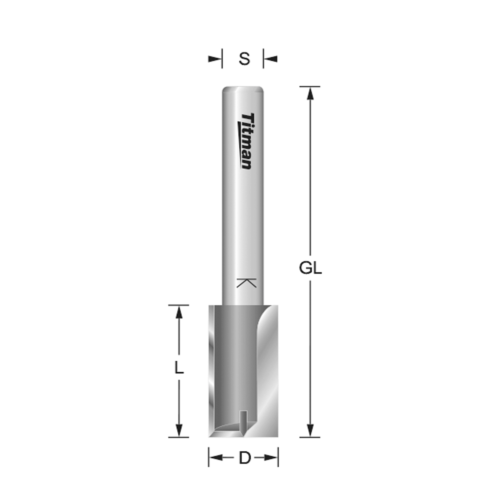

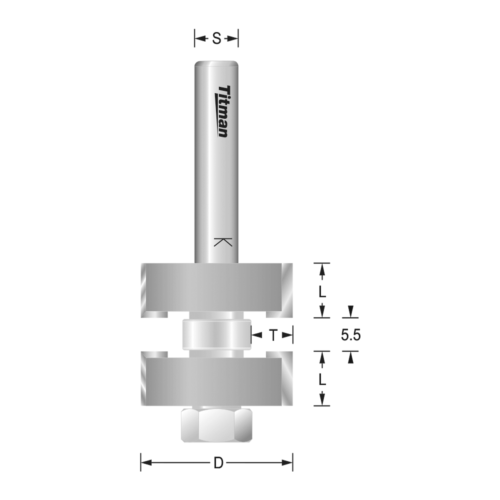

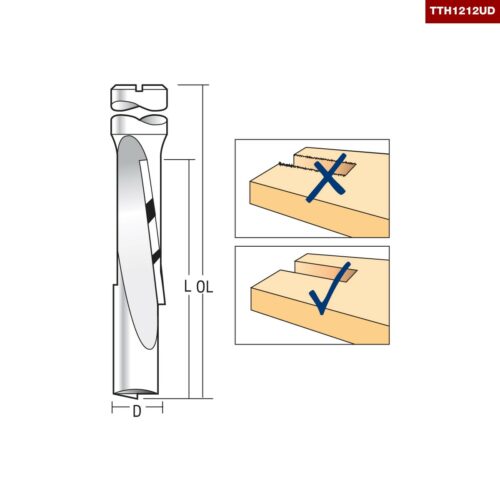

UP/DOWN SHEAR STAGGERED TOOTH TCT A fine finish may be achieved for trimming veneered and double-faced boards, plywoods and natural timbers using these up-down two flute cutters. DESCRIPTION A fine finish may be achieved for trimming veneered and double-faced boards, plywoods and natural timbers using these up-down two flute cutters.

UP/DOWN SHEAR STAGGERED TOOTH TCT A fine finish may be achieved for trimming veneered and double-faced boards, plywoods and natural timbers using these up-down two flute cutters. DESCRIPTION A fine finish may be achieved for trimming veneered and double-faced boards, plywoods and natural timbers using these up-down two flute cutters. -

Solid Carbide Burrs Ideally suited for freehand stock removal, weld preparation and finishing of nimonic alloy components. A smooth finish can be achieved on metal, plastic and other materials. RPM for each product in this range: TTSCB1 - 10,000-30,000 TTSCB2 - 20,000-90,000 TTSCB3 - 10,000-30,000 TTSCB4 - 20,000-50,000 TTSCB5 - 10,000-30,000 TTSCB6 - 20,000-50,000 TTSCB7 - 10,000-30,000 TTSCB8 - 10,000-30,000 TTSCB9 and TTSCB95 - 20,000-50,000 TTSCB10 - 20,000-50,000 TTSCB11-TTSCB14 - 20,000-50,006

Solid Carbide Burrs Ideally suited for freehand stock removal, weld preparation and finishing of nimonic alloy components. A smooth finish can be achieved on metal, plastic and other materials. RPM for each product in this range: TTSCB1 - 10,000-30,000 TTSCB2 - 20,000-90,000 TTSCB3 - 10,000-30,000 TTSCB4 - 20,000-50,000 TTSCB5 - 10,000-30,000 TTSCB6 - 20,000-50,000 TTSCB7 - 10,000-30,000 TTSCB8 - 10,000-30,000 TTSCB9 and TTSCB95 - 20,000-50,000 TTSCB10 - 20,000-50,000 TTSCB11-TTSCB14 - 20,000-50,006