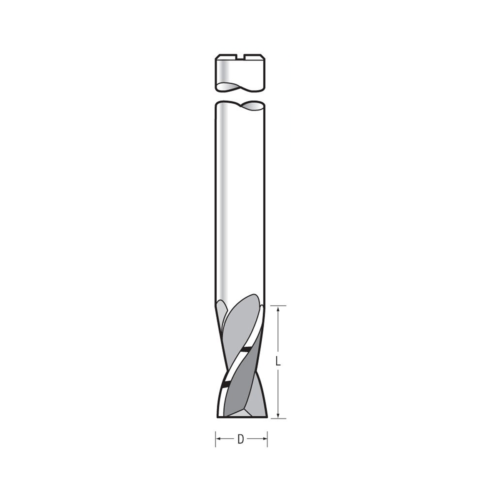

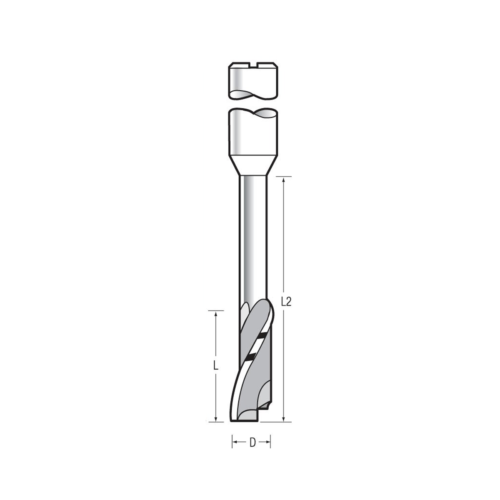

A range of solid carbide spiral flute designed router cutters for use on general wood based materials, hardwood, softwood, MDF, HDF, chipboard, plywood, with certain styles designed specifically for use on acrylics, composites and light metals. The polychristalline diamond tools in this section offer greater performance when used for joining, sizing, folding and grooving chipboard coated and veneered panels, laminate and mineral boards.

-

Solid Carbide Burrs Ideally suited for freehand stock removal, weld preparation and finishing of nimonic alloy components. A smooth finish can be achieved on metal, plastic and other materials. RPM for each product in this range: TTSCB1 - 10,000-30,000 TTSCB2 - 20,000-90,000 TTSCB3 - 10,000-30,000 TTSCB4 - 20,000-50,000 TTSCB5 - 10,000-30,000 TTSCB6 - 20,000-50,000 TTSCB7 - 10,000-30,000 TTSCB8 - 10,000-30,000 TTSCB9 and TTSCB95 - 20,000-50,000 TTSCB10 - 20,000-50,000 TTSCB11-TTSCB14 - 20,000-50,006

Solid Carbide Burrs Ideally suited for freehand stock removal, weld preparation and finishing of nimonic alloy components. A smooth finish can be achieved on metal, plastic and other materials. RPM for each product in this range: TTSCB1 - 10,000-30,000 TTSCB2 - 20,000-90,000 TTSCB3 - 10,000-30,000 TTSCB4 - 20,000-50,000 TTSCB5 - 10,000-30,000 TTSCB6 - 20,000-50,000 TTSCB7 - 10,000-30,000 TTSCB8 - 10,000-30,000 TTSCB9 and TTSCB95 - 20,000-50,000 TTSCB10 - 20,000-50,000 TTSCB11-TTSCB14 - 20,000-50,006 -

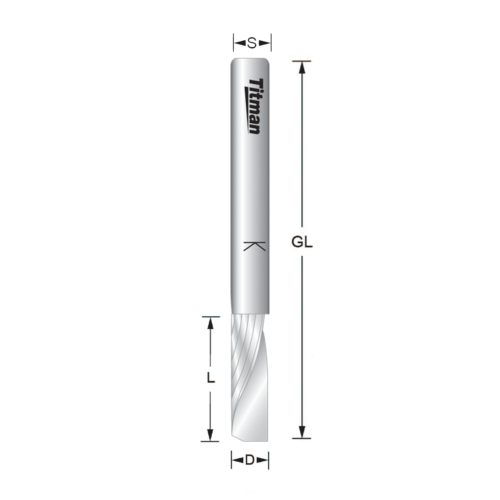

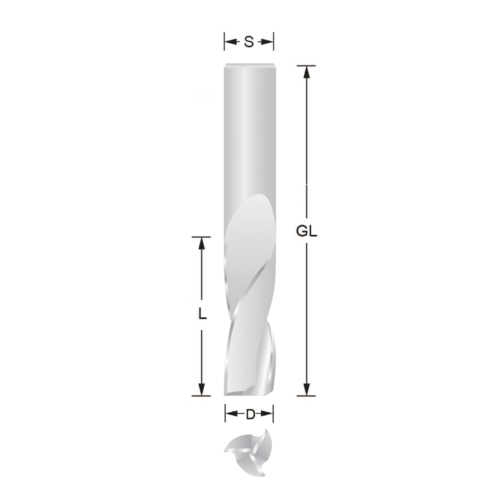

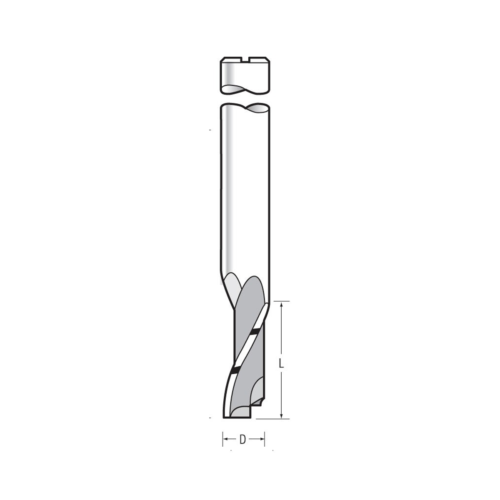

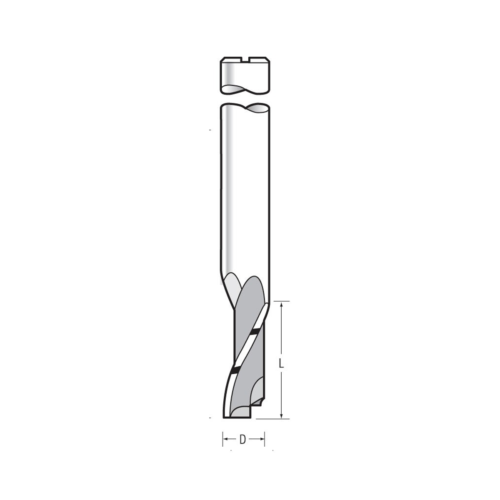

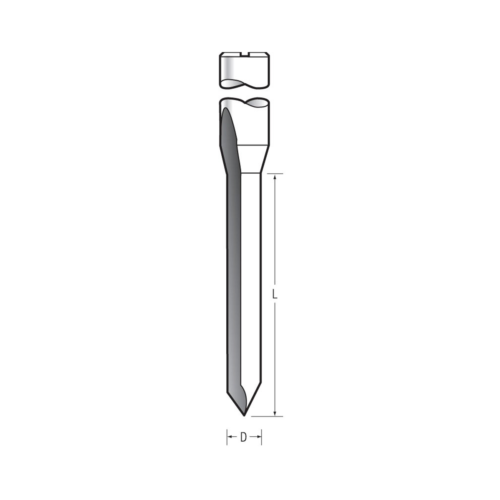

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.