-

A particular advantage to this replacement tip style over the conventional brazed variety is that the diameter remains constant. These double and single flute style flush trim router cutters are designed for use on template and pattern work and can be used in hand-held and table-mounted routers. They have a shank mounted bearing which will run along and follow the template which is attached to the workpiece with the end result being an exact duplicate of the template itself. The L209-OH tip has one cutting edge and is non reversible, the others are reversible. Tips are sold in boxes on 10.

A particular advantage to this replacement tip style over the conventional brazed variety is that the diameter remains constant. These double and single flute style flush trim router cutters are designed for use on template and pattern work and can be used in hand-held and table-mounted routers. They have a shank mounted bearing which will run along and follow the template which is attached to the workpiece with the end result being an exact duplicate of the template itself. The L209-OH tip has one cutting edge and is non reversible, the others are reversible. Tips are sold in boxes on 10. -

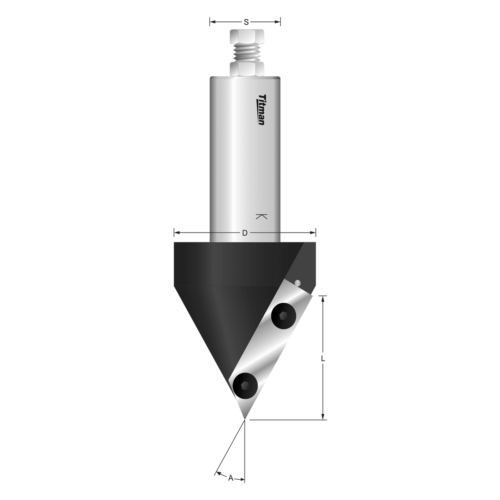

This range of single flute RT cutters are used to produce chamfers and are ideal for V grooves on softwood, hardwood, MDF and other manmade materials. The design and the specially ground tip produce a perfect V in the bottom of the groove. Angles are measured from the vertical, i.e. a TTVGC60SFRT-1/2 has an inclusive angle of 120 degrees on the tool. Cutters come complete with one tip already installed, the L308 tips are reversible the others are non reversble. Tips are sold in boxes of 10.

This range of single flute RT cutters are used to produce chamfers and are ideal for V grooves on softwood, hardwood, MDF and other manmade materials. The design and the specially ground tip produce a perfect V in the bottom of the groove. Angles are measured from the vertical, i.e. a TTVGC60SFRT-1/2 has an inclusive angle of 120 degrees on the tool. Cutters come complete with one tip already installed, the L308 tips are reversible the others are non reversble. Tips are sold in boxes of 10. -

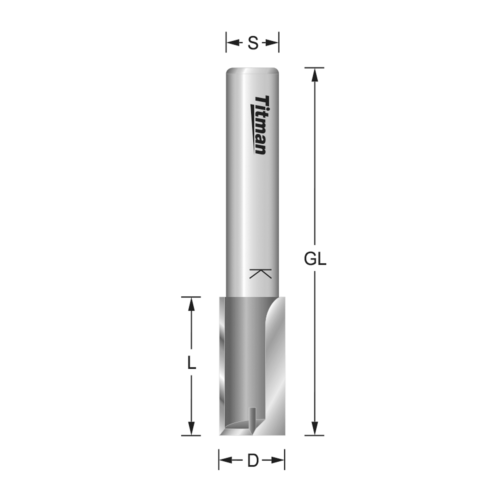

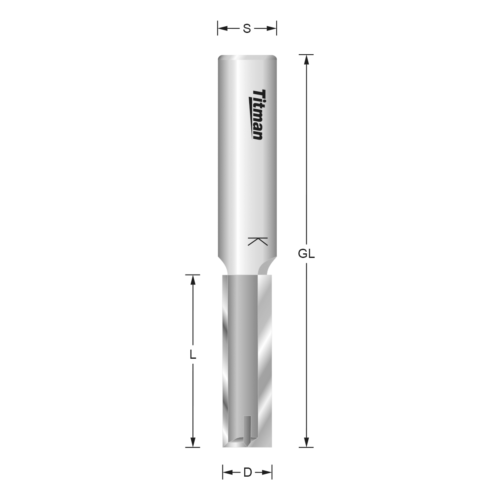

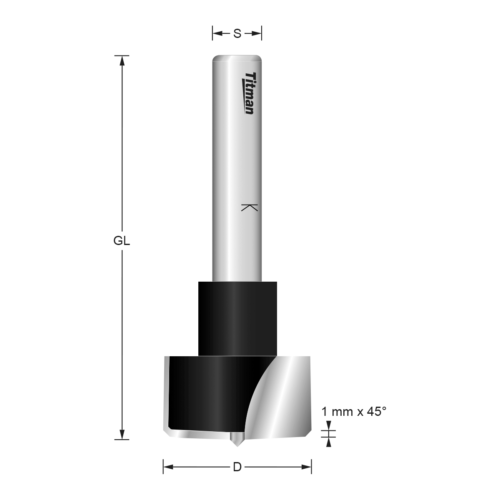

DESCRIPTION A comprehensive range of straight fluted router cutters with diameters from 1.5mm to 50.8mm with parallel and internally threaded shank configurations. There are some left hand rotational cutters in this range. Part numbers starting with TTWLC are for use in inlay work and have a chisel point end. TTPH do not plunge.

DESCRIPTION A comprehensive range of straight fluted router cutters with diameters from 1.5mm to 50.8mm with parallel and internally threaded shank configurations. There are some left hand rotational cutters in this range. Part numbers starting with TTWLC are for use in inlay work and have a chisel point end. TTPH do not plunge. -

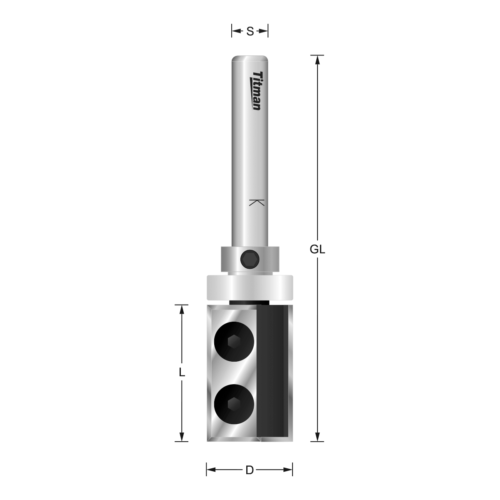

Widely used for copy profiling and flush trimming . Aluminium cutting reference numbers TTSIBGT90LK-1/2 , TTSIBGT90LK-1/4 Downward shear cutter action reference numbers TTBGT90LKS-1/2, TTBGT90LKS-1/4, TTBGT90LKS-12, TTBGT90LKS-6, TTBGT90LKS-8, TTBGT90S-1/4, TTBGT90S-6, TTBGT90S-8, cutters have a downward shear cutting action. Top and Bottom bearing guided reference numbers TBGT90LK1DB-1/2, TTBGT90LK2DB-1/2, TTBGT90LK2DB-12, TTBGT90LK2DB-4-1/2, TTBGT90LKDB-1/2, TTBGT90LKDB-8 TTBGT90LKSLP-1/4, TTBGT90SLP-1/4 have a low profile end screw for restrictive access applications. Oversize bearing cutters reference numbers TTIBGT63LK-B375-1/4, TIBGT63LK-B375-6 have an oversize bottom bearing for overhang trimming. TTSET1214-1/4 has a solid end bearing for heavy duty work.

Widely used for copy profiling and flush trimming . Aluminium cutting reference numbers TTSIBGT90LK-1/2 , TTSIBGT90LK-1/4 Downward shear cutter action reference numbers TTBGT90LKS-1/2, TTBGT90LKS-1/4, TTBGT90LKS-12, TTBGT90LKS-6, TTBGT90LKS-8, TTBGT90S-1/4, TTBGT90S-6, TTBGT90S-8, cutters have a downward shear cutting action. Top and Bottom bearing guided reference numbers TBGT90LK1DB-1/2, TTBGT90LK2DB-1/2, TTBGT90LK2DB-12, TTBGT90LK2DB-4-1/2, TTBGT90LKDB-1/2, TTBGT90LKDB-8 TTBGT90LKSLP-1/4, TTBGT90SLP-1/4 have a low profile end screw for restrictive access applications. Oversize bearing cutters reference numbers TTIBGT63LK-B375-1/4, TIBGT63LK-B375-6 have an oversize bottom bearing for overhang trimming. TTSET1214-1/4 has a solid end bearing for heavy duty work. -

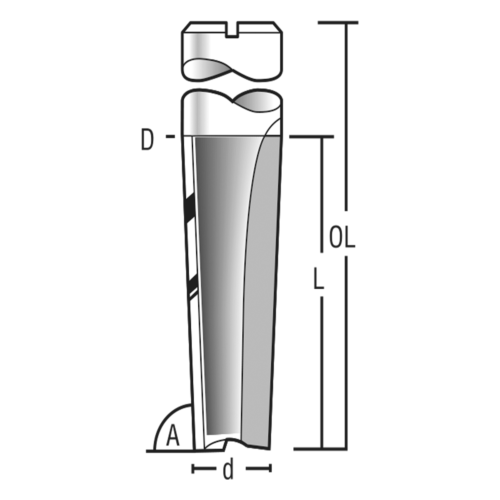

DESCRIPTION Ideal for veining work, freehand decor for panels and useful for character lining work on sign writing applications in solid timbers. The angle ( measurement A ) is measured from the horizontal. TTVGC45SF-1/2, TTVGC45SF-1/4, TTVGC45SF-12, TTVGC60SF-1/2, TTVGC60SF-1/4, TTVGC60SF-12, TTVGC60SF-8 cut to a point. TTVGCB45-1/4, TTVGCB60-127-1/4 have a shank mounted bearing.

DESCRIPTION Ideal for veining work, freehand decor for panels and useful for character lining work on sign writing applications in solid timbers. The angle ( measurement A ) is measured from the horizontal. TTVGC45SF-1/2, TTVGC45SF-1/4, TTVGC45SF-12, TTVGC60SF-1/2, TTVGC60SF-1/4, TTVGC60SF-12, TTVGC60SF-8 cut to a point. TTVGCB45-1/4, TTVGCB60-127-1/4 have a shank mounted bearing. -

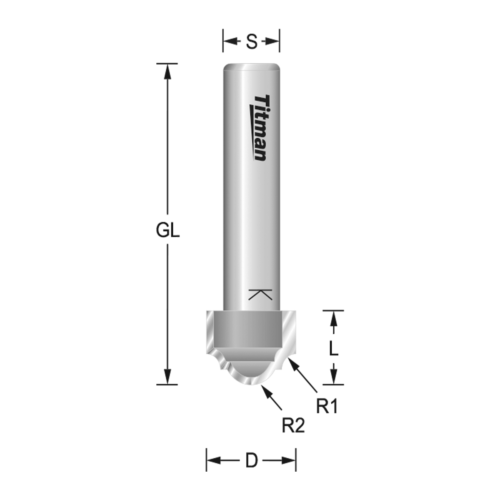

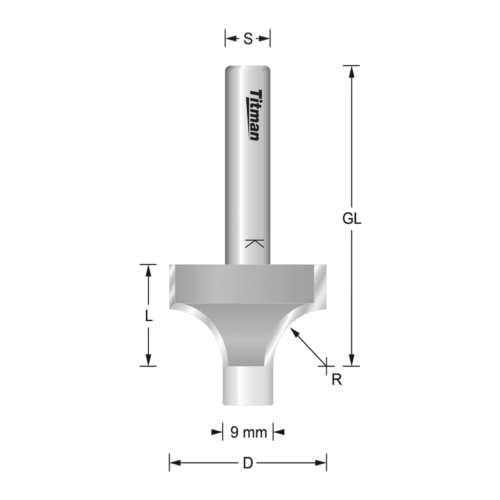

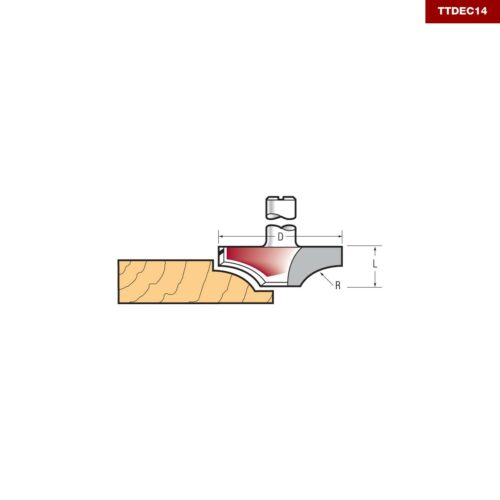

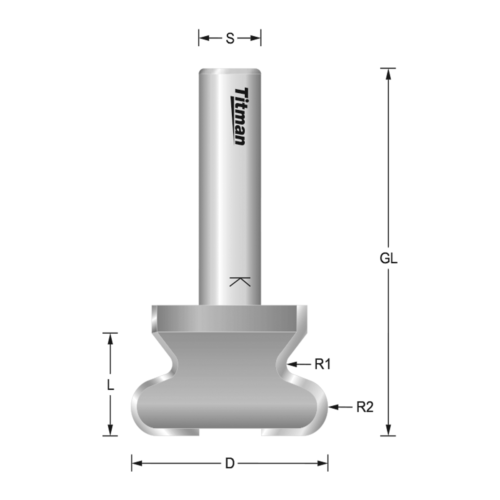

TCT Cove Mould Bearing Guided Producing a quarter round on the edge of the workpiece these are ideal for detailing casework, doors and drawers, posts and columns. The cove also makes up one-half of the rule joint used on drop-leaf tables. DESCRIPTION These cutters come complete with TTB127 and TTB16 bearings. Matching rounding over cutters available for rule joints.

TCT Cove Mould Bearing Guided Producing a quarter round on the edge of the workpiece these are ideal for detailing casework, doors and drawers, posts and columns. The cove also makes up one-half of the rule joint used on drop-leaf tables. DESCRIPTION These cutters come complete with TTB127 and TTB16 bearings. Matching rounding over cutters available for rule joints. -

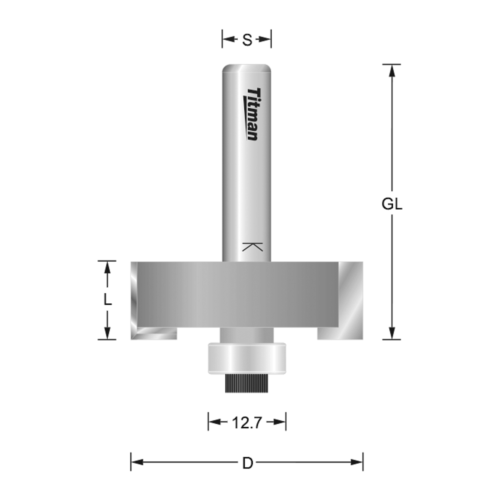

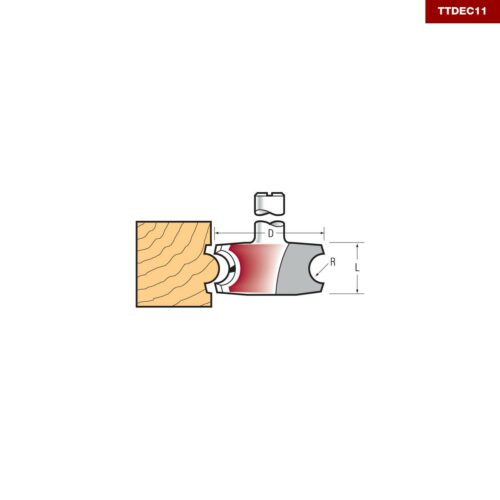

CT Finger Pull Grip Square Bottom For solid handles and pulls on kitchen and wall unit doors, the perfect solutions for providing positive grips and softened, easy-on-the-fingers edges without the need for external hardware. DESCRIPTION TTFPC22 is a variation of TTFPC19 giving a square bottom and undercut. Both of these have a centre tip for plunging

CT Finger Pull Grip Square Bottom For solid handles and pulls on kitchen and wall unit doors, the perfect solutions for providing positive grips and softened, easy-on-the-fingers edges without the need for external hardware. DESCRIPTION TTFPC22 is a variation of TTFPC19 giving a square bottom and undercut. Both of these have a centre tip for plunging -

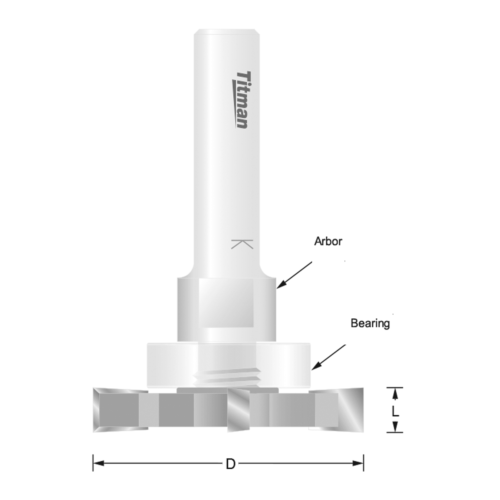

TCT Groover Consists of Groover, Bearing and Arbor. Can be supplied for 10, 15 and 20mm strip. DESCRIPTION Consists of Groover, Bearing and Arbor. Can be supplied for 10, 15, 20 and 25mm strip. For slotting doors with a portable routing machine, using a Guide Bearing to give the correct cutting depth of 4mm. Suits Therma Seal Intumescent Strip.

TCT Groover Consists of Groover, Bearing and Arbor. Can be supplied for 10, 15 and 20mm strip. DESCRIPTION Consists of Groover, Bearing and Arbor. Can be supplied for 10, 15, 20 and 25mm strip. For slotting doors with a portable routing machine, using a Guide Bearing to give the correct cutting depth of 4mm. Suits Therma Seal Intumescent Strip. -

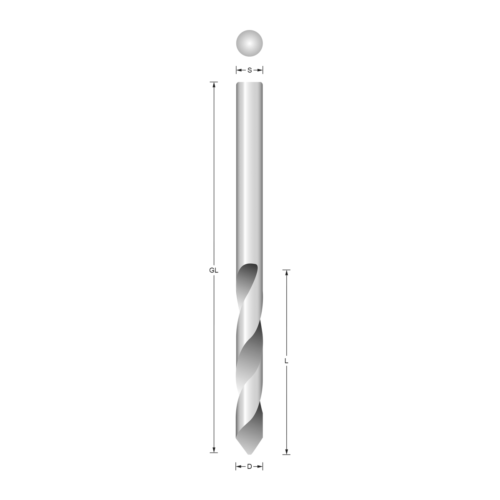

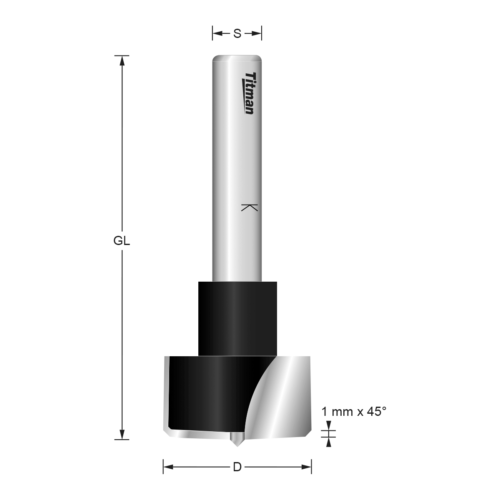

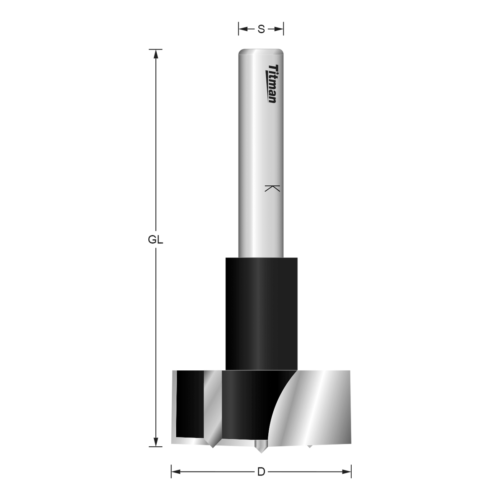

2 Wing with C/Point without Scribers TCT 2 wing available with or without scribers and parallel shanks. DESCRIPTION 2 wing available with or without scribers and parallel shanks. Right hand with centre point. Left hand available to special order - please contact the Sales Department for details. For boring bits at above 80mm overall length please contact the Sales Department for pricing and availability. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Select correct boring bit design for machine, material and thickness: Drill or Boring Machines: Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM.

2 Wing with C/Point without Scribers TCT 2 wing available with or without scribers and parallel shanks. DESCRIPTION 2 wing available with or without scribers and parallel shanks. Right hand with centre point. Left hand available to special order - please contact the Sales Department for details. For boring bits at above 80mm overall length please contact the Sales Department for pricing and availability. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Select correct boring bit design for machine, material and thickness: Drill or Boring Machines: Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM. -

DESCRIPTION 2 wing with centre point and with or without scribers and parallel shanks. Right hand with centre point. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM.

DESCRIPTION 2 wing with centre point and with or without scribers and parallel shanks. Right hand with centre point. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM. -

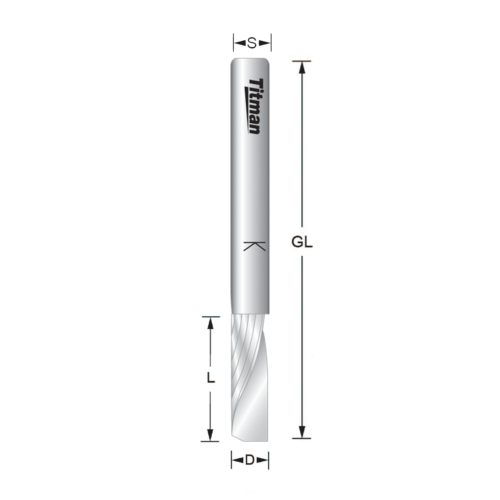

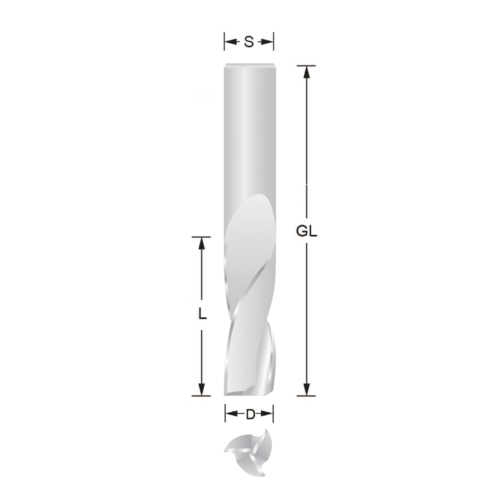

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.