-

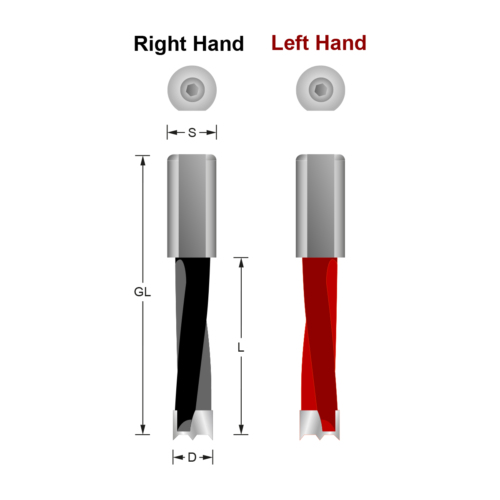

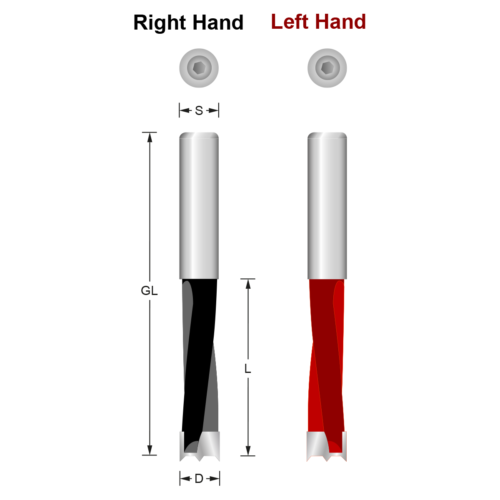

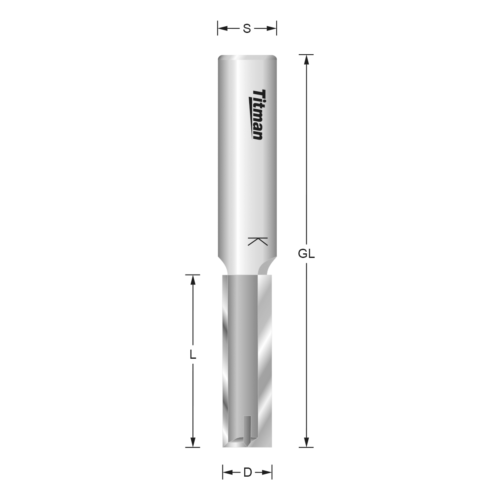

DESCRIPTION A comprehensive range of straight fluted router cutters with diameters from 1.5mm to 50.8mm with parallel and internally threaded shank configurations. There are some left hand rotational cutters in this range. Part numbers starting with TTWLC are for use in inlay work and have a chisel point end. TTPH do not plunge.

DESCRIPTION A comprehensive range of straight fluted router cutters with diameters from 1.5mm to 50.8mm with parallel and internally threaded shank configurations. There are some left hand rotational cutters in this range. Part numbers starting with TTWLC are for use in inlay work and have a chisel point end. TTPH do not plunge. -

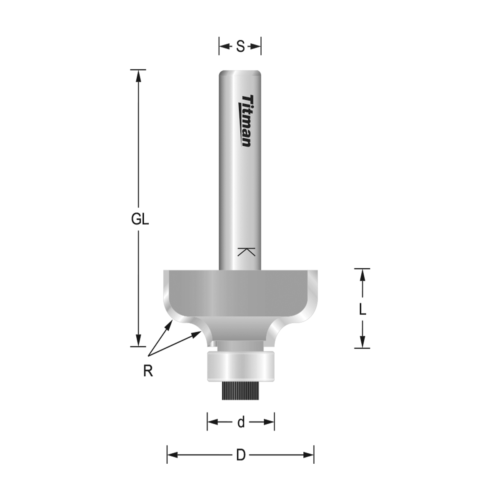

Widely used for copy profiling and flush trimming . Aluminium cutting reference numbers TTSIBGT90LK-1/2 , TTSIBGT90LK-1/4 Downward shear cutter action reference numbers TTBGT90LKS-1/2, TTBGT90LKS-1/4, TTBGT90LKS-12, TTBGT90LKS-6, TTBGT90LKS-8, TTBGT90S-1/4, TTBGT90S-6, TTBGT90S-8, cutters have a downward shear cutting action. Top and Bottom bearing guided reference numbers TBGT90LK1DB-1/2, TTBGT90LK2DB-1/2, TTBGT90LK2DB-12, TTBGT90LK2DB-4-1/2, TTBGT90LKDB-1/2, TTBGT90LKDB-8 TTBGT90LKSLP-1/4, TTBGT90SLP-1/4 have a low profile end screw for restrictive access applications. Oversize bearing cutters reference numbers TTIBGT63LK-B375-1/4, TIBGT63LK-B375-6 have an oversize bottom bearing for overhang trimming. TTSET1214-1/4 has a solid end bearing for heavy duty work.

Widely used for copy profiling and flush trimming . Aluminium cutting reference numbers TTSIBGT90LK-1/2 , TTSIBGT90LK-1/4 Downward shear cutter action reference numbers TTBGT90LKS-1/2, TTBGT90LKS-1/4, TTBGT90LKS-12, TTBGT90LKS-6, TTBGT90LKS-8, TTBGT90S-1/4, TTBGT90S-6, TTBGT90S-8, cutters have a downward shear cutting action. Top and Bottom bearing guided reference numbers TBGT90LK1DB-1/2, TTBGT90LK2DB-1/2, TTBGT90LK2DB-12, TTBGT90LK2DB-4-1/2, TTBGT90LKDB-1/2, TTBGT90LKDB-8 TTBGT90LKSLP-1/4, TTBGT90SLP-1/4 have a low profile end screw for restrictive access applications. Oversize bearing cutters reference numbers TTIBGT63LK-B375-1/4, TIBGT63LK-B375-6 have an oversize bottom bearing for overhang trimming. TTSET1214-1/4 has a solid end bearing for heavy duty work. -

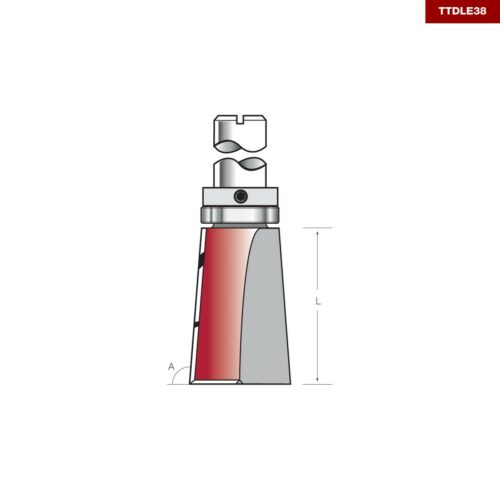

DESCRIPTION Ideal for veining work, freehand decor for panels and useful for character lining work on sign writing applications in solid timbers. The angle ( measurement A ) is measured from the horizontal. TTVGC45SF-1/2, TTVGC45SF-1/4, TTVGC45SF-12, TTVGC60SF-1/2, TTVGC60SF-1/4, TTVGC60SF-12, TTVGC60SF-8 cut to a point. TTVGCB45-1/4, TTVGCB60-127-1/4 have a shank mounted bearing.

DESCRIPTION Ideal for veining work, freehand decor for panels and useful for character lining work on sign writing applications in solid timbers. The angle ( measurement A ) is measured from the horizontal. TTVGC45SF-1/2, TTVGC45SF-1/4, TTVGC45SF-12, TTVGC60SF-1/2, TTVGC60SF-1/4, TTVGC60SF-12, TTVGC60SF-8 cut to a point. TTVGCB45-1/4, TTVGCB60-127-1/4 have a shank mounted bearing. -

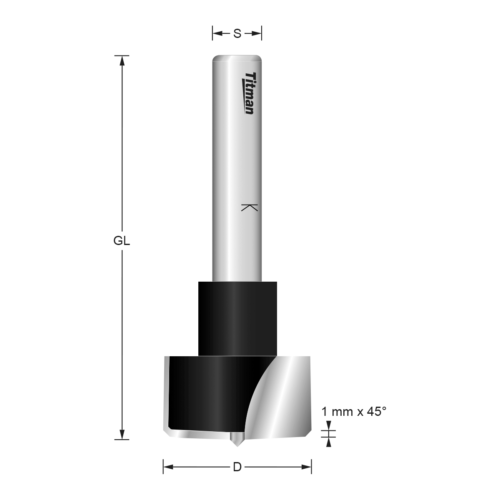

TCT Bevelled A range of various angles of beveled cutters designed to chamfer sections of timber, chipboard and MDF. DESCRIPTION The cutters with reference TTBCF have a tungsten carbide plunging centre tip The cutters with reference TTBC are for profiling only and do not plunge. Angles are measured from the vertical

TCT Bevelled A range of various angles of beveled cutters designed to chamfer sections of timber, chipboard and MDF. DESCRIPTION The cutters with reference TTBCF have a tungsten carbide plunging centre tip The cutters with reference TTBC are for profiling only and do not plunge. Angles are measured from the vertical -

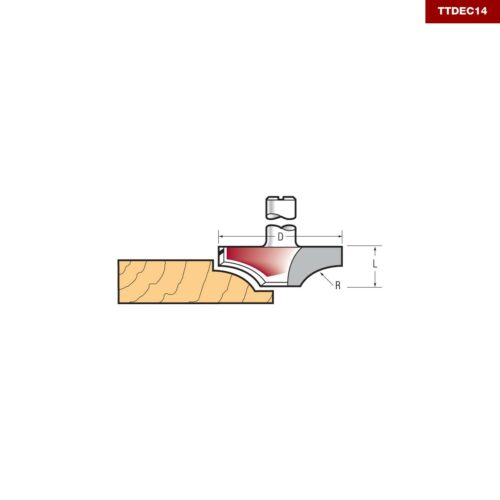

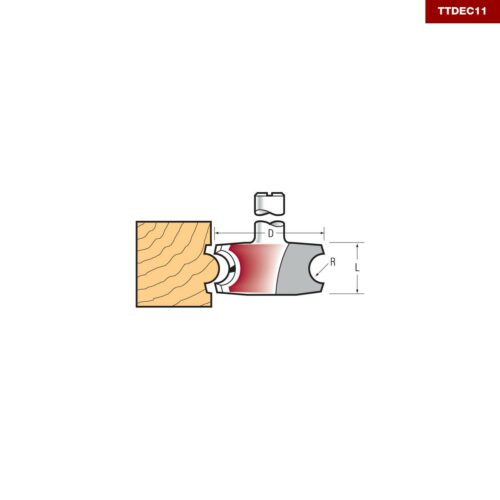

TCT Dovetail Standard sizes for all dovetail and sliding dovetail applications ie slot dovetail, hidden dovetail, etc. DESCRIPTION Available with scribers on TTDCS14.3-8 & TTDCS127-1/4 to enable use in conjunction with portable routing jigs. Parts TTADC12B-1/4, TTBDC14B-1/4 have shank mounted bearings fitted.

TCT Dovetail Standard sizes for all dovetail and sliding dovetail applications ie slot dovetail, hidden dovetail, etc. DESCRIPTION Available with scribers on TTDCS14.3-8 & TTDCS127-1/4 to enable use in conjunction with portable routing jigs. Parts TTADC12B-1/4, TTBDC14B-1/4 have shank mounted bearings fitted. -

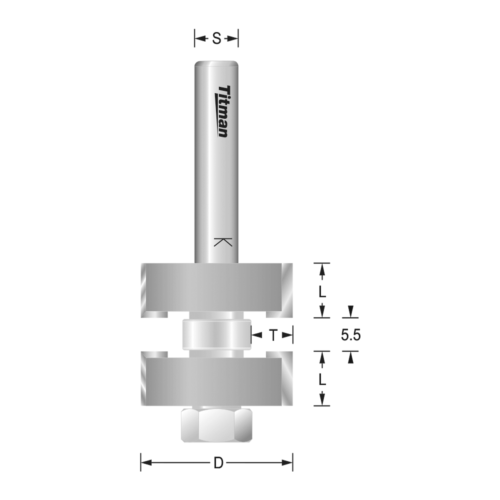

Slitting saws for use with arbors TTLDTA and TTMGA6.35 When using this arbor TTMGA6.35 the screw head is only 1.5mm beyond the groover. The use of a bearing with 8 mm bore is possible on the shank side. These can be found in the bearings section through the main heading on the home page. TTLDTA Arbor inclusive spacers and bearing no. B16 (D = 16). Further bearings with bore 6,35 mm can be found in the bearings section through the main heading on the home page.

Slitting saws for use with arbors TTLDTA and TTMGA6.35 When using this arbor TTMGA6.35 the screw head is only 1.5mm beyond the groover. The use of a bearing with 8 mm bore is possible on the shank side. These can be found in the bearings section through the main heading on the home page. TTLDTA Arbor inclusive spacers and bearing no. B16 (D = 16). Further bearings with bore 6,35 mm can be found in the bearings section through the main heading on the home page. -

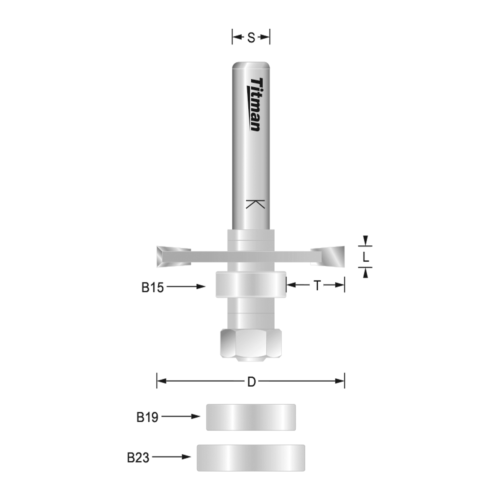

TCT Biscuit Joint Biscuit Joint Slotter with Arbor self guided. Comes with 3 interchangeable bearings to produce slots for the popular biscuit sizes of 0,10 and 20. Ideal for hardwood, softwoods, ply, MDF and chipboard. DESCRIPTION Z=Number of flutes. RPM=Maximum revolutions per minute Groove Depth with various bearings are as follows TTB15 = 12.5mm, TTB19 = 10.5mm, TTB23 = 8.5mm.

TCT Biscuit Joint Biscuit Joint Slotter with Arbor self guided. Comes with 3 interchangeable bearings to produce slots for the popular biscuit sizes of 0,10 and 20. Ideal for hardwood, softwoods, ply, MDF and chipboard. DESCRIPTION Z=Number of flutes. RPM=Maximum revolutions per minute Groove Depth with various bearings are as follows TTB15 = 12.5mm, TTB19 = 10.5mm, TTB23 = 8.5mm. -

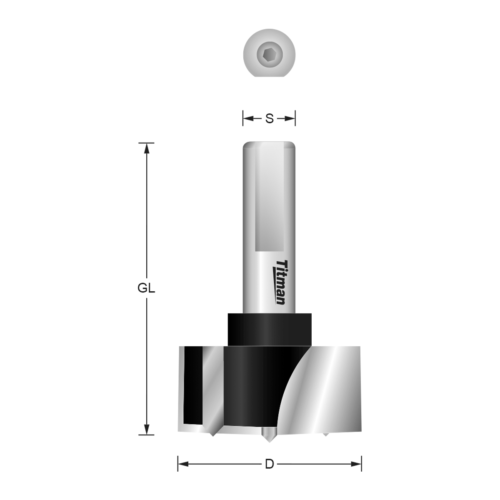

2 Wing with C/Point without Scribers TCT 2 wing available with or without scribers and parallel shanks. DESCRIPTION 2 wing available with or without scribers and parallel shanks. Right hand with centre point. Left hand available to special order - please contact the Sales Department for details. For boring bits at above 80mm overall length please contact the Sales Department for pricing and availability. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Select correct boring bit design for machine, material and thickness: Drill or Boring Machines: Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM.

2 Wing with C/Point without Scribers TCT 2 wing available with or without scribers and parallel shanks. DESCRIPTION 2 wing available with or without scribers and parallel shanks. Right hand with centre point. Left hand available to special order - please contact the Sales Department for details. For boring bits at above 80mm overall length please contact the Sales Department for pricing and availability. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Select correct boring bit design for machine, material and thickness: Drill or Boring Machines: Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM. -

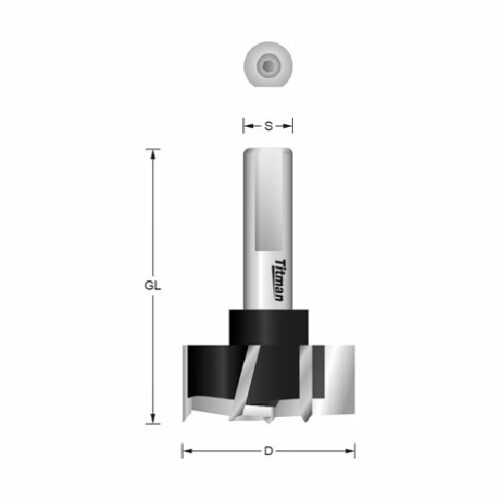

DESCRIPTION 2 wing with or without centre point and with or without scribers, shanks are 10mm with flat on one side and end adjusting screw. Right hand with centre point. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM.

DESCRIPTION 2 wing with or without centre point and with or without scribers, shanks are 10mm with flat on one side and end adjusting screw. Right hand with centre point. These boring bits must be used in fixed head machines only, never in hand-held routing machines or hand-held drills. Softwood, Chipboard - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Hardwood - Use Scribers: 15mm-35mm 3000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. MDF - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 1500 RPM. Laminate - Use Scribers: 15mm-35mm 3000-6000 RPM, 35mm-50mm 3000 RPM, 50mm-100mm 2000 RPM. Diameters of 20mm and above with Scribers will burn at over 6000 RPM. Do not use Scribers on solid laminates. Router Machines: Softwood, Hardwood, Chipboard, MDF, Laminate - No Scribers over 6000RPM: 15mm-35mm 10000 RPM, 35mm-50mm 6000 RPM, 50mm-100mm 3000 RPM. -

Left Hand Rotation 3 Wing With 3 Scribers and Centre Point A comprehensive range of hinge borers. Please ensure correct variation is selected when ordering. DESCRIPTION A comprehensive range of hinge borers. All are available in 57mm overall lengths. Some 2 wing with 2 scribers cutters are also available in 70mm and 77mm overall lengths. All have 10mm diameter Left Hand or Right Hand Shanks. Shanks have flat on one side and length adjusting screw. Some sizes are also available with or without centre point. The TTTMB range have a removable/replaceable centre point with a 'V' point effect at one end, flush finish at the other end. Please ensure correct variation is selected when ordering. For use on Multi-Boring machines.

Left Hand Rotation 3 Wing With 3 Scribers and Centre Point A comprehensive range of hinge borers. Please ensure correct variation is selected when ordering. DESCRIPTION A comprehensive range of hinge borers. All are available in 57mm overall lengths. Some 2 wing with 2 scribers cutters are also available in 70mm and 77mm overall lengths. All have 10mm diameter Left Hand or Right Hand Shanks. Shanks have flat on one side and length adjusting screw. Some sizes are also available with or without centre point. The TTTMB range have a removable/replaceable centre point with a 'V' point effect at one end, flush finish at the other end. Please ensure correct variation is selected when ordering. For use on Multi-Boring machines. -

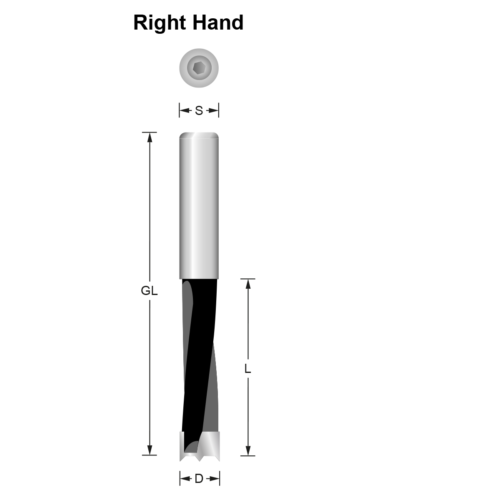

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.

STC Spiral The accepted solid carbide cutter for machining and routing acrylics, plastics and Perspex. The helical cut gives a much easier lead into the material preventing snatching and chipping on cut. DESCRIPTION Perfect preparation before flame polishing of Perspex. Downcut for chip-free finish on MFC. DC in product code denotes Downcut. * = For use on very fine acrylics where downward cutting action will prevent vibration and component lifting. Use a P.T.F.E. spray to enhance performance and prevent waste from welding to the tool.