-

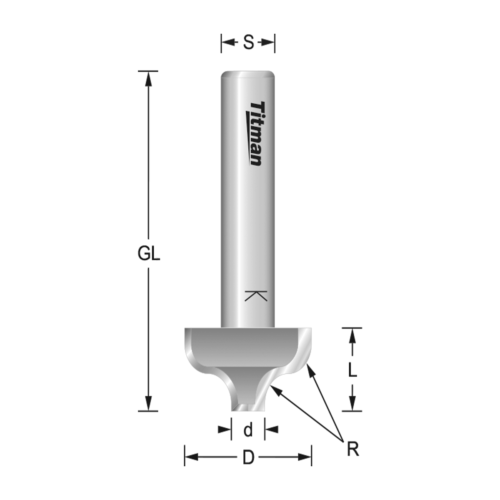

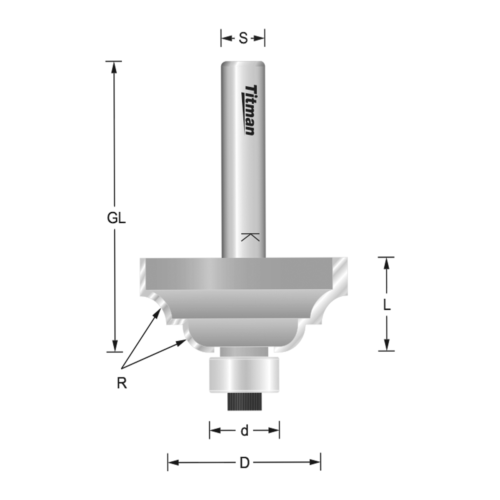

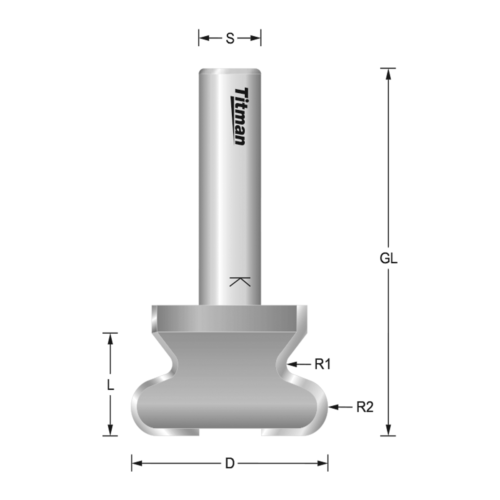

TCT Edge Moulding Shallow Bead A shallow radius style bull nose cutter ideal for a hand hold which is able to plunge into the centre of a board. Designed to finish solid edged worktops for kitchens or display work areas. These have a shallow radius DESCRIPTION The shallow arc is ideal for a hand hold shape rather than a full 180-degree round over, this also has short flats above and below the cutter arc which can produce a small quirk effect for an edge mould for example

TCT Edge Moulding Shallow Bead A shallow radius style bull nose cutter ideal for a hand hold which is able to plunge into the centre of a board. Designed to finish solid edged worktops for kitchens or display work areas. These have a shallow radius DESCRIPTION The shallow arc is ideal for a hand hold shape rather than a full 180-degree round over, this also has short flats above and below the cutter arc which can produce a small quirk effect for an edge mould for example -

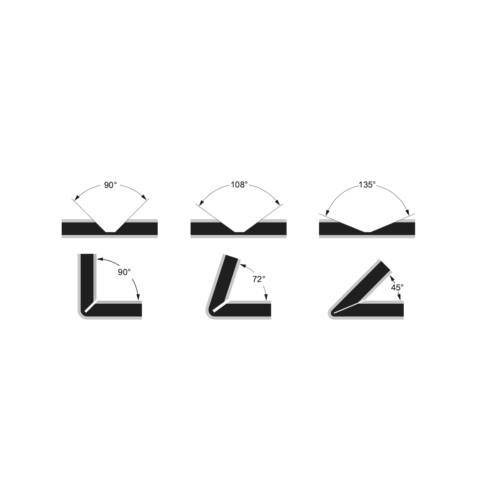

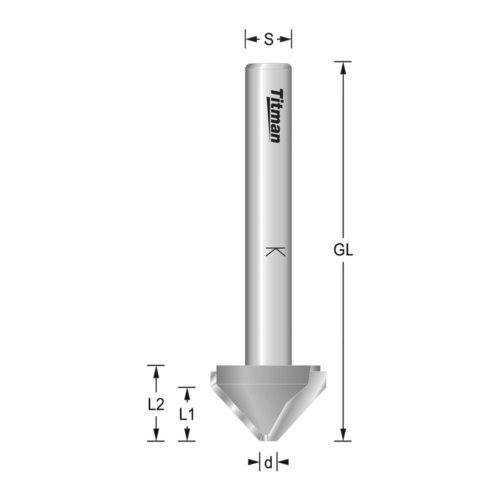

ACM FOLDING AND SCORING TCT These cutters are specially deigned for routing aluminium composite material. Used to rout V-grooves of 90 degree, 108 degree or 135 degree inclusive into the centre of the material for the folding the ACM into a 90 degree, 72 degree or 45 degree corner, this procedure will allow easy foldinging of the material preventing the cracking in the intended folded area.

ACM FOLDING AND SCORING TCT These cutters are specially deigned for routing aluminium composite material. Used to rout V-grooves of 90 degree, 108 degree or 135 degree inclusive into the centre of the material for the folding the ACM into a 90 degree, 72 degree or 45 degree corner, this procedure will allow easy foldinging of the material preventing the cracking in the intended folded area. -

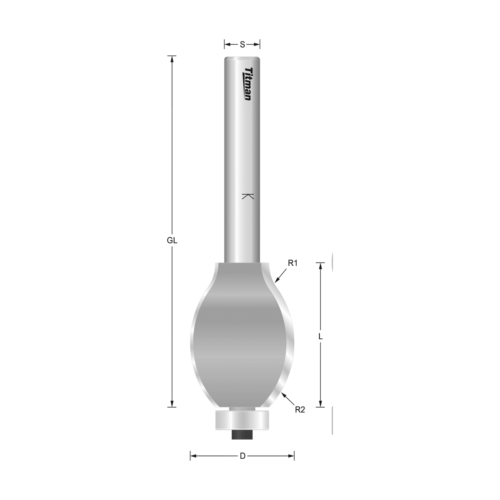

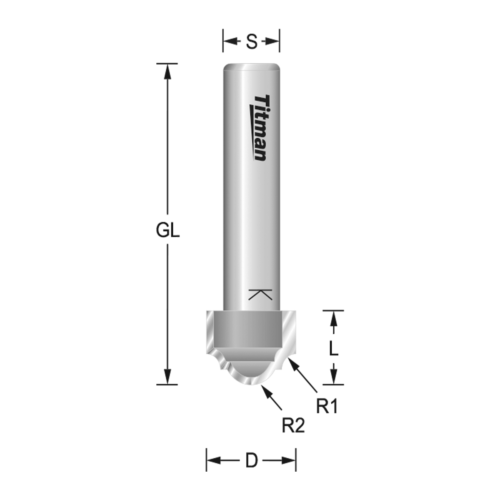

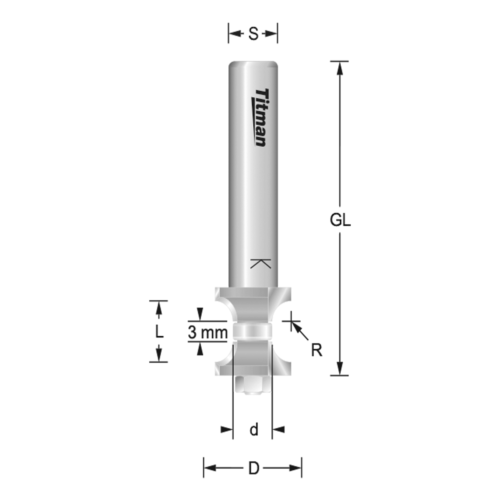

CT Finger Pull Grip Square Bottom For solid handles and pulls on kitchen and wall unit doors, the perfect solutions for providing positive grips and softened, easy-on-the-fingers edges without the need for external hardware. DESCRIPTION TTFPC22 is a variation of TTFPC19 giving a square bottom and undercut. Both of these have a centre tip for plunging

CT Finger Pull Grip Square Bottom For solid handles and pulls on kitchen and wall unit doors, the perfect solutions for providing positive grips and softened, easy-on-the-fingers edges without the need for external hardware. DESCRIPTION TTFPC22 is a variation of TTFPC19 giving a square bottom and undercut. Both of these have a centre tip for plunging -

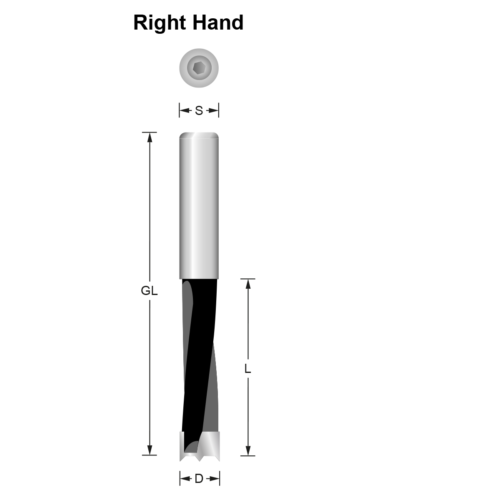

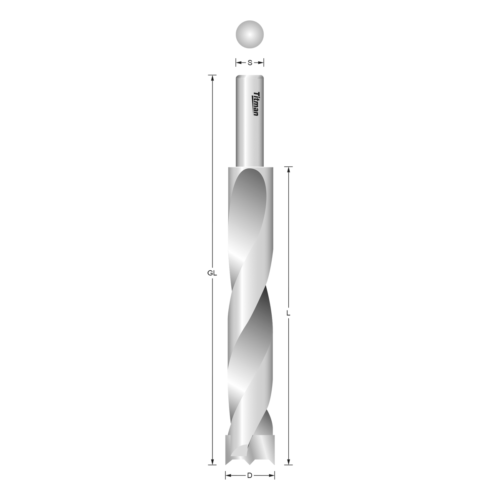

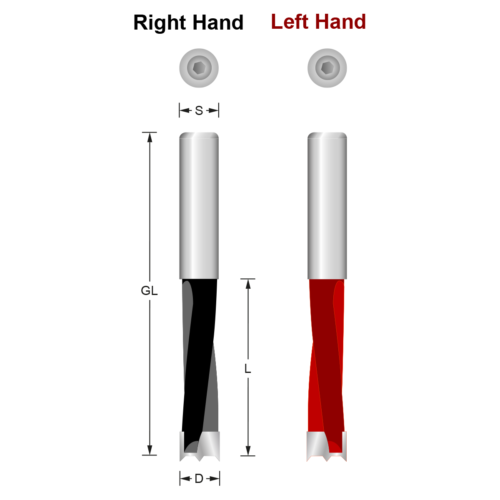

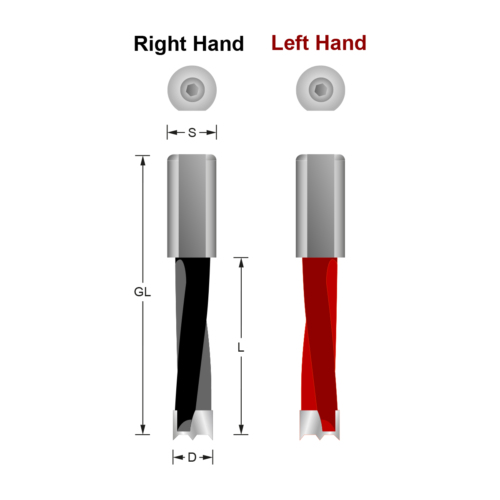

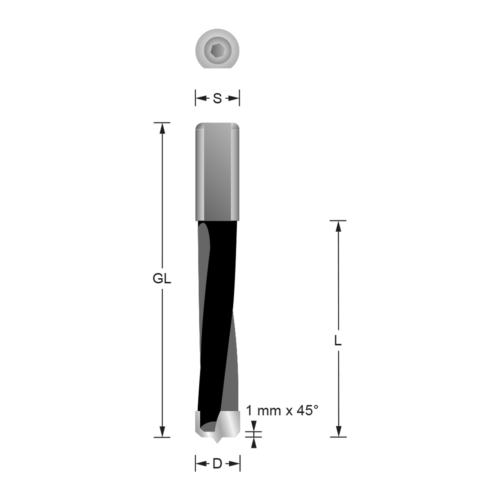

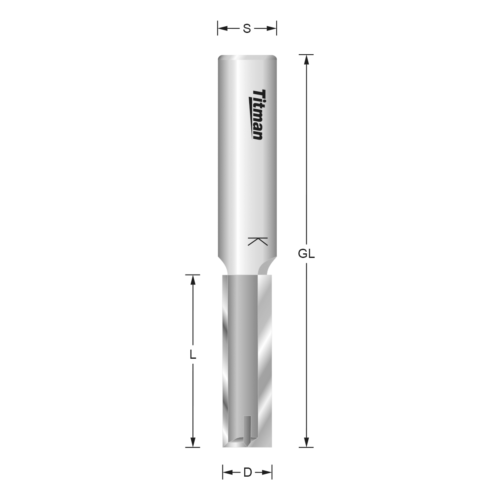

DESCRIPTION A comprehensive range of straight fluted router cutters with diameters from 1.5mm to 50.8mm with parallel and internally threaded shank configurations. There are some left hand rotational cutters in this range. Part numbers starting with TTWLC are for use in inlay work and have a chisel point end. TTPH do not plunge.

DESCRIPTION A comprehensive range of straight fluted router cutters with diameters from 1.5mm to 50.8mm with parallel and internally threaded shank configurations. There are some left hand rotational cutters in this range. Part numbers starting with TTWLC are for use in inlay work and have a chisel point end. TTPH do not plunge. -

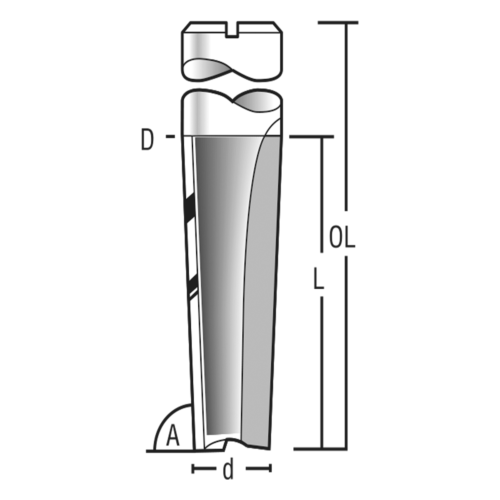

Widely used for copy profiling and flush trimming . Aluminium cutting reference numbers TTSIBGT90LK-1/2 , TTSIBGT90LK-1/4 Downward shear cutter action reference numbers TTBGT90LKS-1/2, TTBGT90LKS-1/4, TTBGT90LKS-12, TTBGT90LKS-6, TTBGT90LKS-8, TTBGT90S-1/4, TTBGT90S-6, TTBGT90S-8, cutters have a downward shear cutting action. Top and Bottom bearing guided reference numbers TBGT90LK1DB-1/2, TTBGT90LK2DB-1/2, TTBGT90LK2DB-12, TTBGT90LK2DB-4-1/2, TTBGT90LKDB-1/2, TTBGT90LKDB-8 TTBGT90LKSLP-1/4, TTBGT90SLP-1/4 have a low profile end screw for restrictive access applications. Oversize bearing cutters reference numbers TTIBGT63LK-B375-1/4, TIBGT63LK-B375-6 have an oversize bottom bearing for overhang trimming. TTSET1214-1/4 has a solid end bearing for heavy duty work.

Widely used for copy profiling and flush trimming . Aluminium cutting reference numbers TTSIBGT90LK-1/2 , TTSIBGT90LK-1/4 Downward shear cutter action reference numbers TTBGT90LKS-1/2, TTBGT90LKS-1/4, TTBGT90LKS-12, TTBGT90LKS-6, TTBGT90LKS-8, TTBGT90S-1/4, TTBGT90S-6, TTBGT90S-8, cutters have a downward shear cutting action. Top and Bottom bearing guided reference numbers TBGT90LK1DB-1/2, TTBGT90LK2DB-1/2, TTBGT90LK2DB-12, TTBGT90LK2DB-4-1/2, TTBGT90LKDB-1/2, TTBGT90LKDB-8 TTBGT90LKSLP-1/4, TTBGT90SLP-1/4 have a low profile end screw for restrictive access applications. Oversize bearing cutters reference numbers TTIBGT63LK-B375-1/4, TIBGT63LK-B375-6 have an oversize bottom bearing for overhang trimming. TTSET1214-1/4 has a solid end bearing for heavy duty work. -

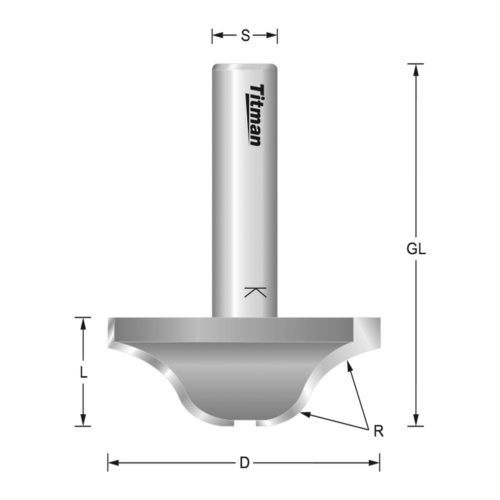

TCT Cove Mould Bearing Guided Producing a quarter round on the edge of the workpiece these are ideal for detailing casework, doors and drawers, posts and columns. The cove also makes up one-half of the rule joint used on drop-leaf tables. DESCRIPTION These cutters come complete with TTB127 and TTB16 bearings. Matching rounding over cutters available for rule joints.

TCT Cove Mould Bearing Guided Producing a quarter round on the edge of the workpiece these are ideal for detailing casework, doors and drawers, posts and columns. The cove also makes up one-half of the rule joint used on drop-leaf tables. DESCRIPTION These cutters come complete with TTB127 and TTB16 bearings. Matching rounding over cutters available for rule joints. -

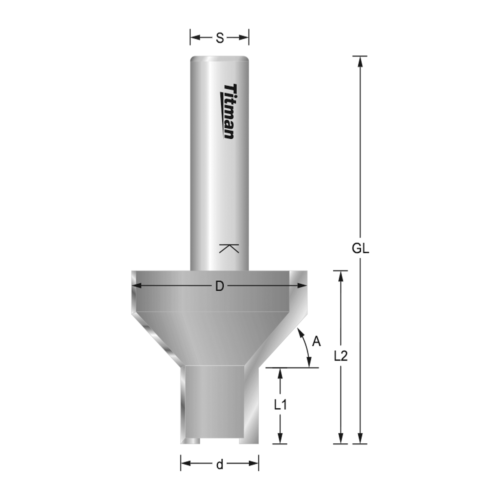

TCT Chamfering Edge Chamfering Edge Cutters. Reducing and Chamfering. DESCRIPTION TTCEC45, TTCECR45, TTLTC4, TTLTCR4, TTLTC63, TTLTCR63 are non plunge but with bottom cut facility. TTCECR45 is the reverse of TTCEC45. TTCECR45L is the reverse of TTCEC45L. TTLTC4 and TTLTCR4 give a lambs tongue effect as TTROB range. TTLTCR4 is the reverse of TTLTC4. TTLTCR63 is the reverse of TTLTC63.

TCT Chamfering Edge Chamfering Edge Cutters. Reducing and Chamfering. DESCRIPTION TTCEC45, TTCECR45, TTLTC4, TTLTCR4, TTLTC63, TTLTCR63 are non plunge but with bottom cut facility. TTCECR45 is the reverse of TTCEC45. TTCECR45L is the reverse of TTCEC45L. TTLTC4 and TTLTCR4 give a lambs tongue effect as TTROB range. TTLTCR4 is the reverse of TTLTC4. TTLTCR63 is the reverse of TTLTC63. -

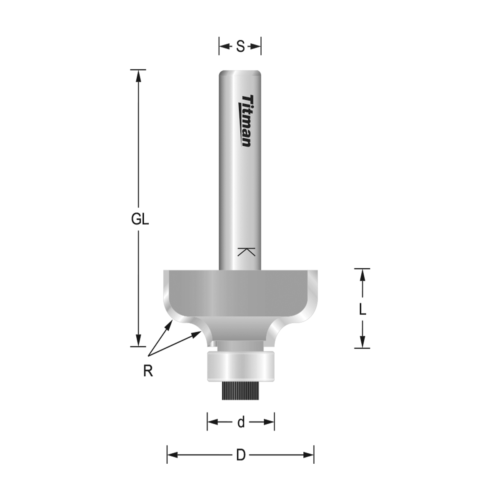

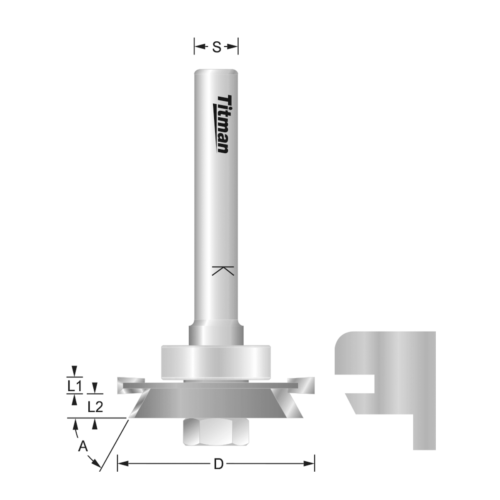

TCT Adjustable Top and Bottom Chamfer with Bearing DESCRIPTION For bevelling and trimming the top and bottom edges of the workpiece. Adjust the four wing trimmer blocks with spacers for differing widths of material. Maximum material thickness 15mm for the DCB16 and is fixed Maximum material thickness 32mm, minimum material thickness 16mm for the BCS38. Maximum material thickness 36mm, minimum material thickness 19mm for the BGAC45. To extend the life of cutting edges use 26mm bearing.

TCT Adjustable Top and Bottom Chamfer with Bearing DESCRIPTION For bevelling and trimming the top and bottom edges of the workpiece. Adjust the four wing trimmer blocks with spacers for differing widths of material. Maximum material thickness 15mm for the DCB16 and is fixed Maximum material thickness 32mm, minimum material thickness 16mm for the BCS38. Maximum material thickness 36mm, minimum material thickness 19mm for the BGAC45. To extend the life of cutting edges use 26mm bearing.